Dezhou Guanlu Precision Machinery Co.,Ltd

Deep hole drilling technology difficulties:

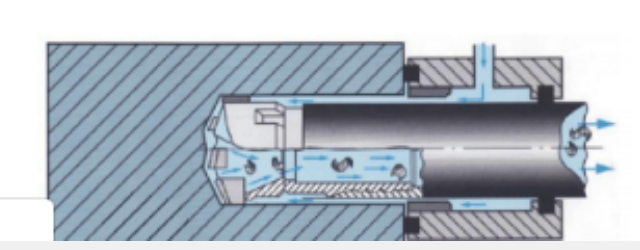

1. Deep hole drilling process is in a closed or half closed working condition,operator could not be able to observe the cutting and tooling status.

2. The cutting happens inside the deep hole,chips discharge path is long,not easy to chips removal.

3. The heat inside the cutting area is not easy to send out.

4. Normally,the hole diameter-hole length ratio is big,when working,the drill bit is easy to vibrate and deviate.

The following matters should be noticed during deep hole drilling process:

1. Main spindle,tools guide bush,tools shank sleeve,and job center rest should be coaxial.

2. Check if the cutting liquid system working in good condition.

3. If the deep hole drilling speed is too high,when the hole nearly finish,better to stop the machine or reduce the speed.

4. Do not stop the machine during deep hole drilling process.If you have to stop the machine,please return the cutting tool some distance.and stop the pump and main spindle.