Dezhou Guanlu Precision Machinery Co.,Ltd

contact us

contact us

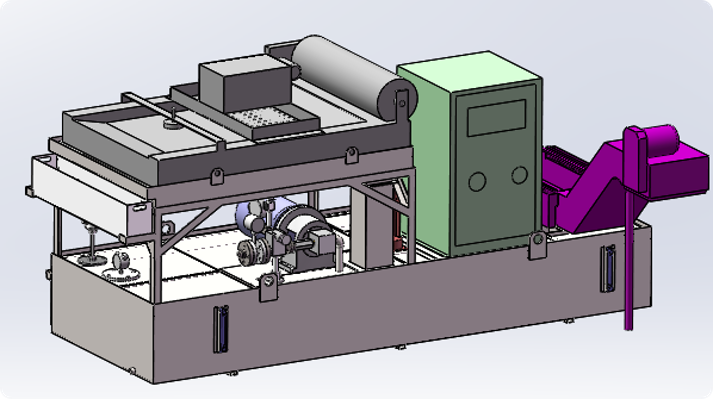

General introduction of Guanlu brand gundrilling machine:

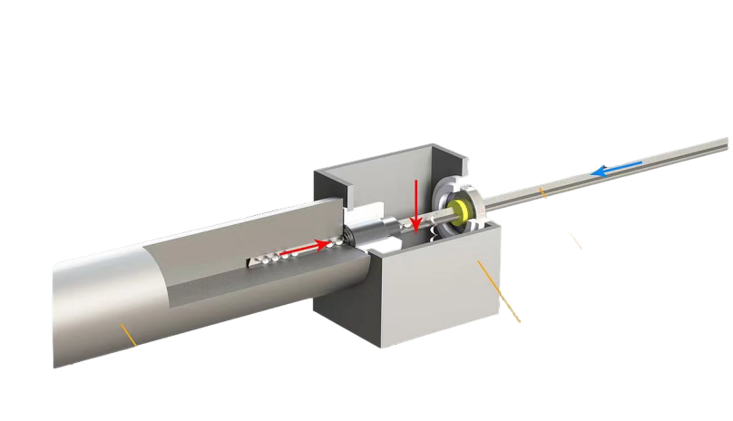

Gun drilling machine method: The cutting oil is supplied from inside of gun drill, and cutting chips are removed from external slot.

Processing capacity:

Drilling diameter range: 2~40mm

Max. drilling depth:4000mm(500/1000/1500/2000/2500 mm/3000mm/4000mm)

Workpiece OD range: Φ15~Φ70mm

many Gun drilling machine models available between the above capacity.

Needs three conditions to get good results for gundrilling process,

1.Good quality gundrills. 2. Machine specially made according to requirements. 3.Suitable cutting liquid

Hole maximum length and diameter ratio: 100:1(special request needs to special designed

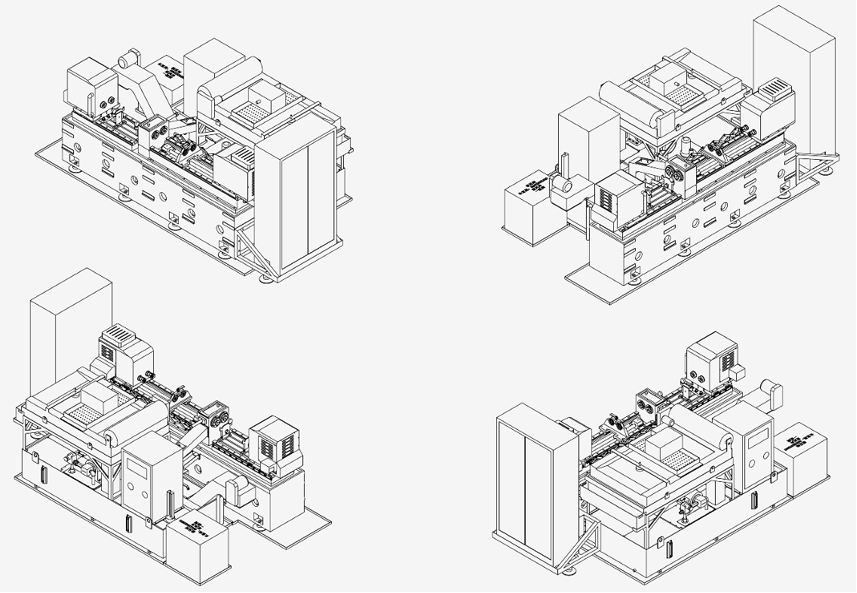

Machine types:

Single spindle gundrilling machine.

Double spindle CNC gundrilling machine.

Four spindle CNC gun drilling machine.

Machine models for selction:

Working modes:

Both workpiece and cutting tool rotate in opposite directions, cutting tool feed.

Workpiece fixed and tool rotate.

Workpiece rotate and the tool fixed.

CNC controller:

GSK,Siemens,Fanuc,Delta PLC

Loading and unloading system is optional

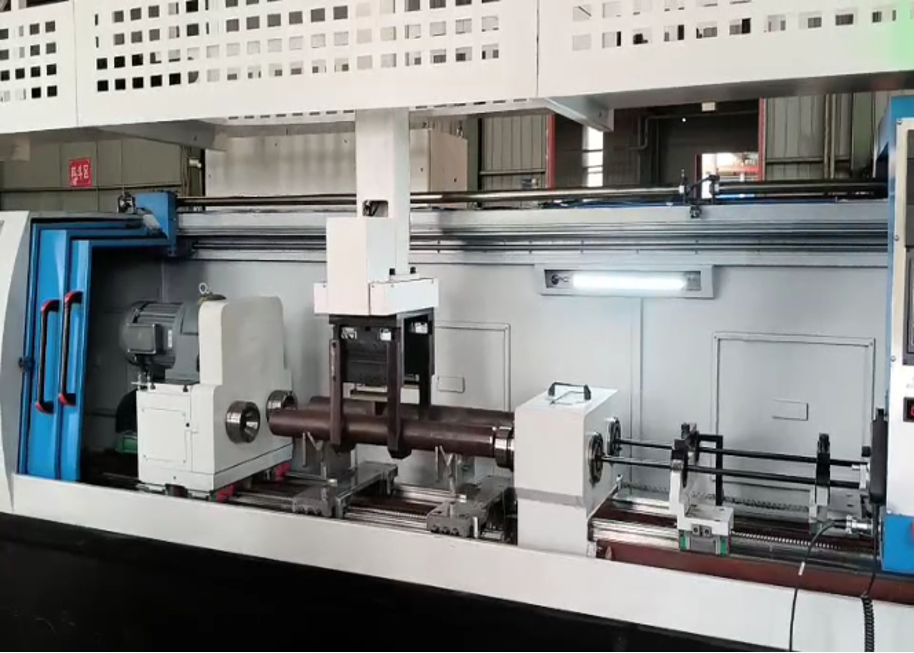

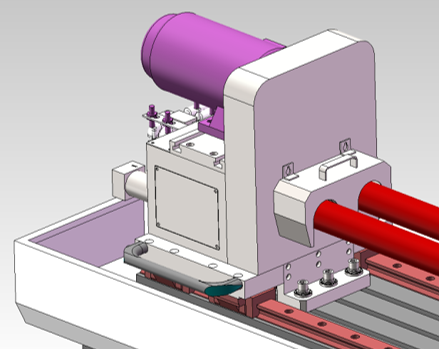

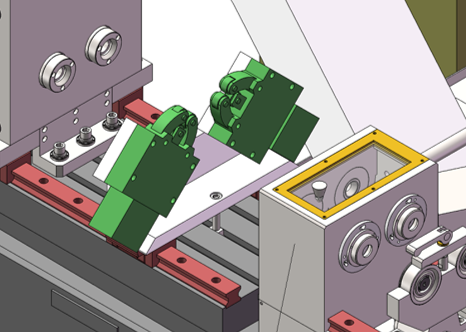

Mainly structure of Guanlu brand gundriling machine:

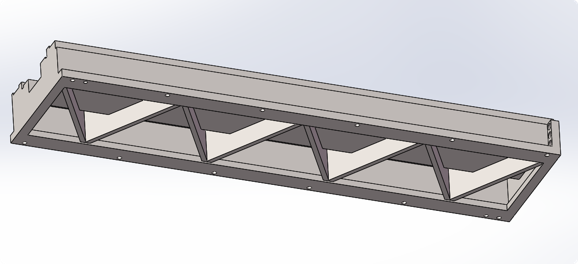

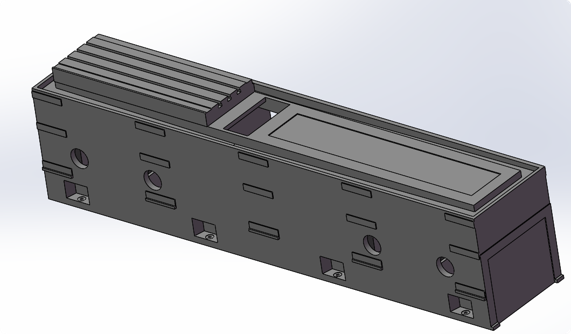

Machine bed

Material : Casting iron HT300

Casting technology : Resin sand wood mold casting

Undergo twice aging treatment to eliminate the internal express, make the machine bed more stable,won’t deform.

The triangular reinforcing ribs inside,make the bed with high precision, long life, strong rigidity and good precision retention

The inclined oil return slot cast around the bed,so that cutting oil can return to oil tank soonest for cycle use

All the machine bed will be inspected strictly .

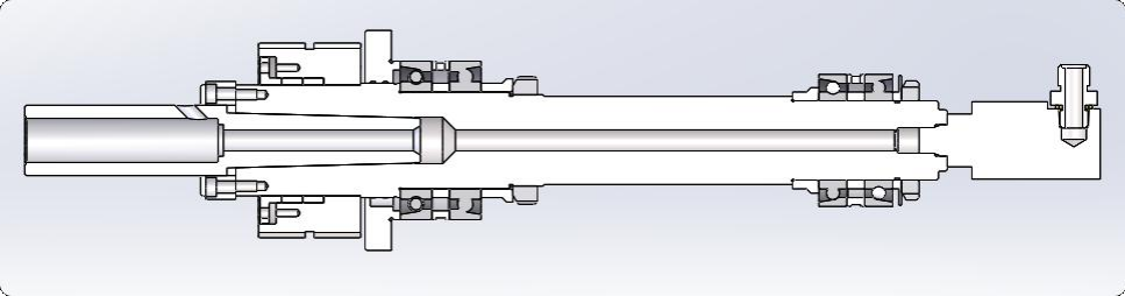

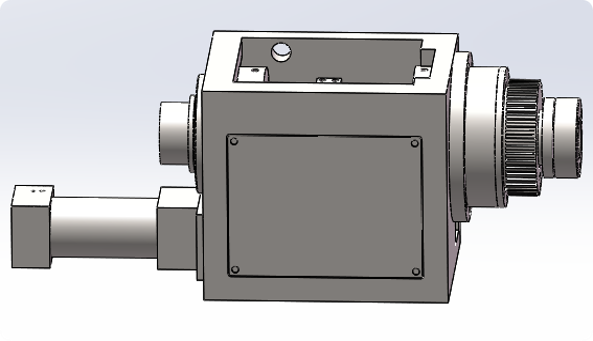

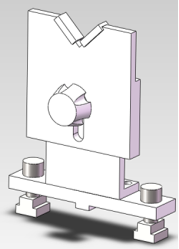

Drill box :

Cast by super casting iron HT300

Drive the cutting tool to rotate ;

The spindle is driven in front, which is beneficial to protect the main motor and easy to exchange the gun drill .

Adopts HIWIN brand rolling linear guide rail, which ensures the stability and precision of the machine .

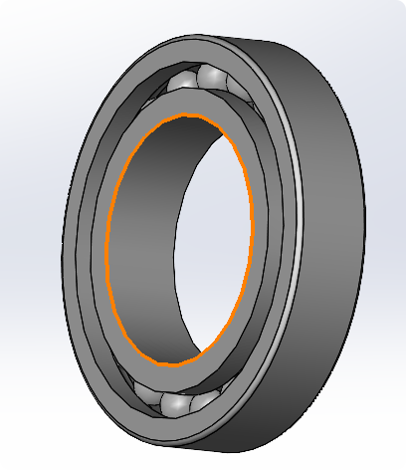

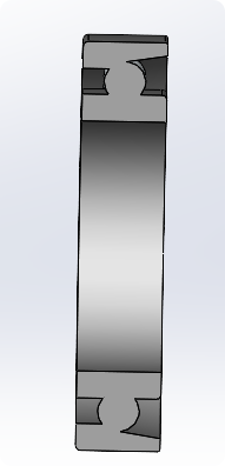

The spindle bearings of the drill box adopts NSK brand high-precision angular contact ball bearings:

Features :

High rotation accuracy,ensure the stability during high-speed running;

High bearing capacity,can withstand both radial and axial loads at same time;

Good high-speed performance,low frication to reduce heating,suitable for high-speed spindle;

Rigidity is adjustable ,can reduce virbration,improve system rigidity;

Long service life and reliable ;

Low temperature+Low noise ;

The rear end of the spindle is equipped with American Deublin rotary joint to provide stable cooling supply for deep hole machining and ensure stable cutting of the machine .

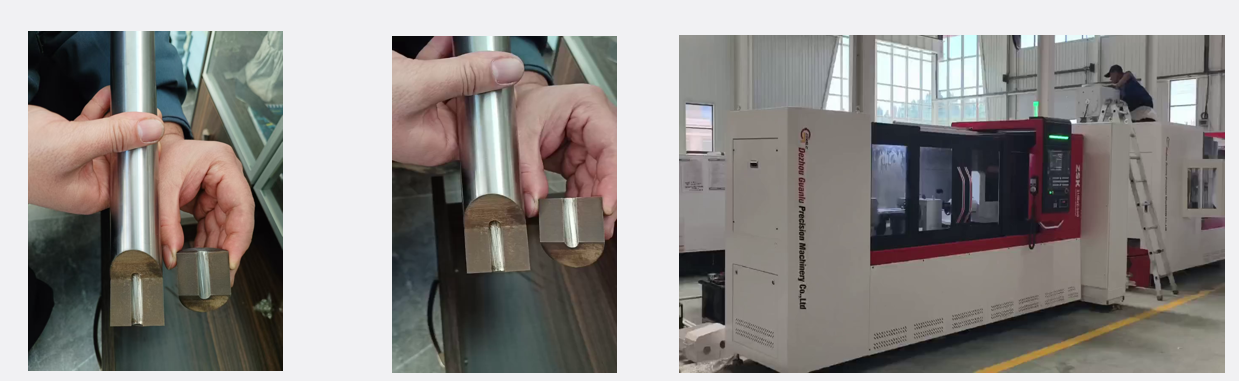

Headstock:

Cast by super casting HT300

Drive the workpiece to rotate, speed fixed;

Adopt high-precision angular contact ball bearings;

The spindle is driven in front,which is convenient to load/unload the workpiece and protect the main motor ;

Headstock is installed on the linear guide rail,easy to adjust its longitudinal position;

The extension and contraction of spindle is controlled by hydraulic system, which can reduce the auxiliary length of cutting tool . If machinehas multi spindles, it can ensure the inlets of all holes are same,good to realize the automatic operation .

Ball Screw:

Adopt structure of servo motor driving the ball screw,with high transmission efficiency,high positioning accuracy and high repeat .

Adopt high-precision angular contact ball bearings

Guide frame:

Cast by super casting iron ;

Remove the cutting chips vertically;

Suport the drill bar .

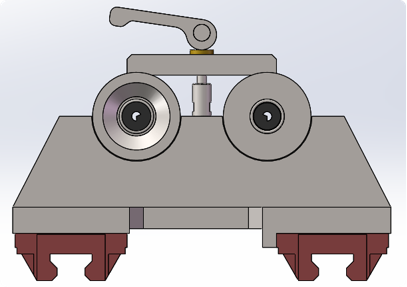

Drill bar support rest :

Cast by super casting iron;

Support the drill bar;

Moving on linear guide rail,agile and simple.

Workpiece carrier :

Used for workpiece pre-positioning,separate with workpiece during processing ;

Hydraulic center rest : (Optional)

Support the workpiece , with function of self-centering ;

The claws are automatically closed or opened under the control of the hydraulic system

Normally used to support the very thin workpiece,such as medical parts

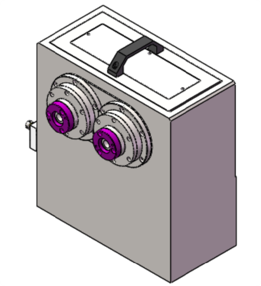

Coolant system :

Including oil tank, Auto chips converyor, Paper filter , Oil chiller, High pressure pump groups, etc. ;

Adopt vertical structure , save space ;

The pressure,level,temperature and flow of cutting oil is displayed on the CNC operation station.

Lubrication System :

The linear guide rail sliders, screw nut, and spindle are uniformly lubricated by the auto lubricating pump station timely and quantitatively ;

Has low-level alarm function .

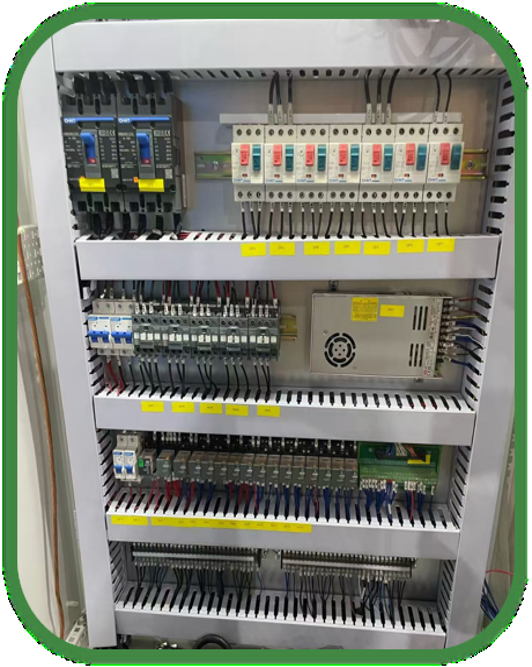

Electric cabinet :

Adopt America Rittal structure, won’t deform;

Main low-volatage electric componets use SCHNEIDER brand ;

With air-conditioner , ensure the electric componets inside, can work under a reasonable temperature, prolong the service life;

With sealing strips to prevent the dust from going inside the electric cabinet ;

Electric cabinet is integral with the machine main body,save space.

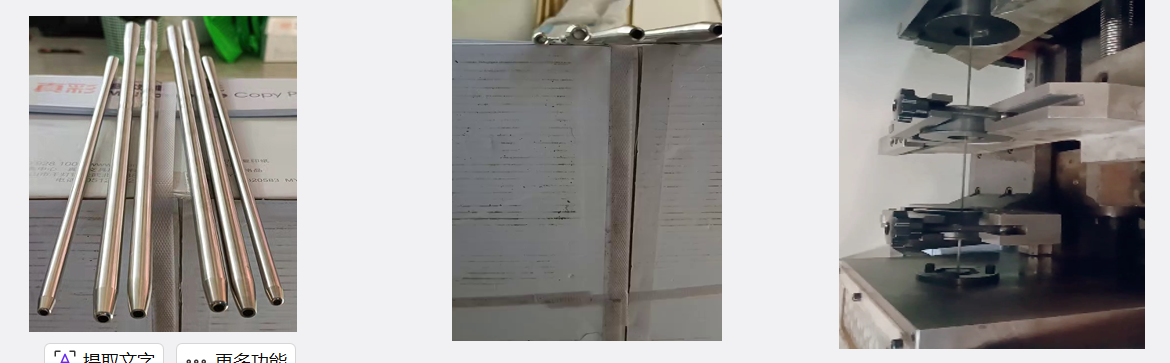

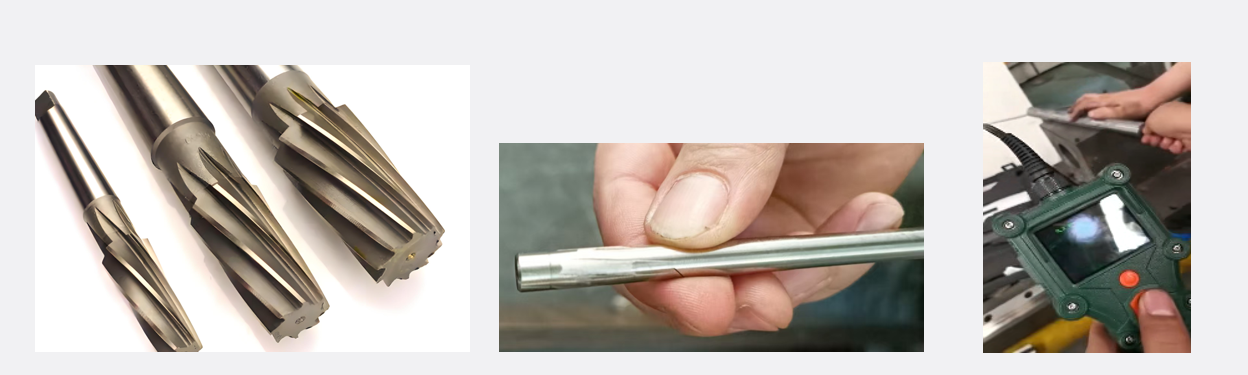

Gun driller and Auxiliary tools (Optional):

Machine Application:

Medical Industry

Workpiece material : Stainless alloy /Titanium alloy 3mm&4mm hole

Military Industry

The machine has drilling and reaming function, and we can make the Broaching Machine as well :

Automobile Industry

Drilling on crankshaft

Thermo well

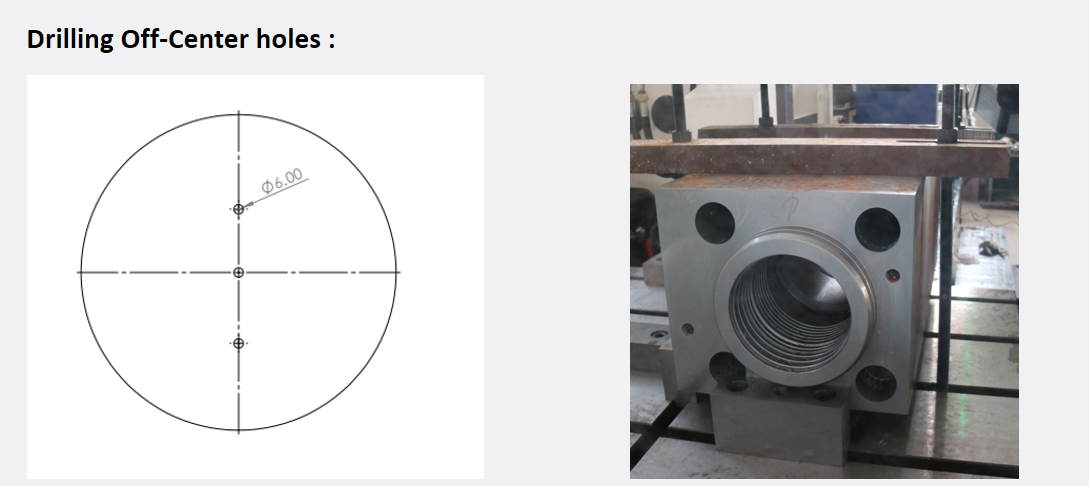

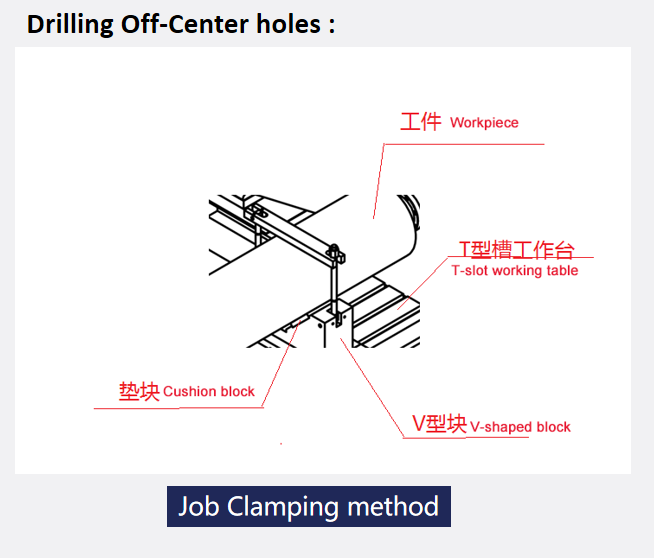

Molds industry

The machine is without headstock;

Fix the job by V-shaped block mounted on the working table, adjust the hole position by putting cashion blocks manually.

If customer want to improve the working efficiency , can choose our Three-coordinate Gundrilling Machine .

Oil and gas industry

Material : AISI 904L,Hole diameter: 8mm,Drill depth: 2000mm ,Hole deviation: 0.8mm/2000mm

BTA drilling an gun drilling combined machine for job works:

Drill range: 6mm -100mm

Drill length:4m

Optical Fiber Industry

Drilling hole on Quartz Glass :

Details about Guanlu and Guanlu Brand gun drilling machine.

Dezhou Guanlu Precision Machinery Co.,Ltd,is founded in year 2011,we are the most famous factory in my local to manufacture deep hole drilling machines. My city Dezhou is the production base of gun drilling machines in China. Almost 70% CNC gun drilling machines are produced here.

We have our own strongly machining facilite, Germany brand Heckert guide grinder,Japanese SNK five face milling center ,chinese most famous planner,VMC,Lathes,box boring machine,milling machine and so on. With these good machning facility,we could be able to manufacture the best quality and best accuracy deep hole machines,under proper management system,we could orgnize production properly,our delivery of machines are stable and in time,we also have some regular models stocks.

Our deep hole gun drilling machine has been exported to more than 50 countries and gained good reputation and fame. We improved our quality and structure day by day.

DZ Guanlu FACTORY advantages compared with other competitors:Our city is the production base of deep hole drilling and boring machines. Among these local competitors,our company is the first choice once clients has visited us and saw our deep hole machines. we have the absulately advantages than others.

Big workshops and Big factory: we have four workshops,one commercial office building and totally 70000square meters working area.

One workshop is 10000square meters.

Two other are 13000 square meters each.

One is 8000 square meters.

All workshops are heavy duty,crane is 32tons,height is 14meters.

Floor foundation loading is 400tons.

Strong machining facilities. Good quality and good accuracy machines are maufactured by good machining machines and skilled workers. We have two sets Germany brand Heckert guide grinder. The guide rail of the deep hole machines are the most important part,it decides the accuracy of machines. after ground by our grinder,the surface of the machine bed likes mirror. Our Japanese brand SNK five face milling machine will work on all the box parts of the BTA drilling machine. Chinee famous brand horizontal boring machine,planning machine,VMC machines,CNC lathe machines.

Most famous technicians. Our company has the most professional technicians. Six engineers totally. All of them had worked in this field for more than 15years. They are full of experience,can design the deep hole machines according to customers request.

Skilled worker teams. Nowadays,it is not easy to hire workers. Especially skilled workers. But our company has special management system to keep these skilled workers. So all of our machines are assembled by skilled workers.

Quality control system,from machine design,parts purchase,parts machining ,machine assemble,machine test running,machine packing,all the process,we have inspection system to warranty the deep hole machine quality.

We use ERP to manage the whole company running system. Every purchase parts,produced parts,machined parts are inspected seriously, all the asseble process are inspected by our inspector.

Our inspection instruments: Renishao laser inferferometer,laser linear meter,roughness meter,time aging meter and so on. ALl of our instruments are inspected every year.

We are the only deep hole machine manufactuer that can sign quality assurance contract and after sale service contract ,so all customer will rest assured after buy our machines.

In time after sale service:

Certificates of our factory:

Guanlu factory passed the ISO9000,Healthy certificate,CE and all necessary certificates.

Some exhibition we have attended and some photos of our customer visiting:

Our deep hole machines have been exported to more than 50countries,most of customers will come to visit us before place orders or inspect machines before shipment. See photos below:

FAQ time:

Q:Are you real deep hole drilling machines manufacturer?

A:Yes,we are 100% real factory manufacturer,who could provide you reliable and eternal after sale service. we are the REAL factory directly sale. VIDEO CALLL ANY TIME.

Q:Can you design the deep hole drilling machines according to our job and our special requirements?

A:Yes,we always accept the customs designed orders. Such as combined gundrilling and BTA drilling machine,deep hole boring SRB machine,barrel screw drilling(eight shape hole)machine,quartz glass drilling machine,BTA drilling and honing combined machine,double end drilling machine and so on.

Q:How many countries have you export,after sale service available?

A:We have exported to more than 50 countries until this year. we have agent in Russia,India,France,Canada,Mexcio and Brail....

Q:What is your deep hole drilling machines warranty ?

A:Normally,our deep hole drilling series machines warranty is for one year,if longer warranty request,we could discuss.

Q:What is your gundrilling machines lead time?

A:For regular gun drilling machine,we have semi machines,which we could build the machine within one month. for the customerized machine,it depends on the design time,about 3month orso.

Q:Will you test the gundrilling machine before shipment?

A:Yes,no matter the client will come to inspect the deep drilling machine before shipment or not,we will test two or three pieces jobs ,in case the machine has problems,we could solve it before shipment.

Q:What is your completely production line?

We are manufacturer of BTA deep hole drilling machine,deep hole honing machine,deep hole gundrillling machine,deep hole skiving roller burnishing machine, three axis/six axis deep hole drilling machine for molds,CNC large lathe,CNC heavy duty lathe,pipe threading machine,slant bed lathe and so on.

Deephole gundrilling machine package when shipping:

Machines will be packed by plastic film,all the small parts are packed into wooden box,while fragile parts such as panels are well packed and protected.Parts inside containers will be well fasten by irons and belts.

Contact us now:

Susan Lee

Mobile/whatsapp/wechat:+8615165964868

Email:dzguanlu@dzguanlu.com

website:www.dzgljc.com