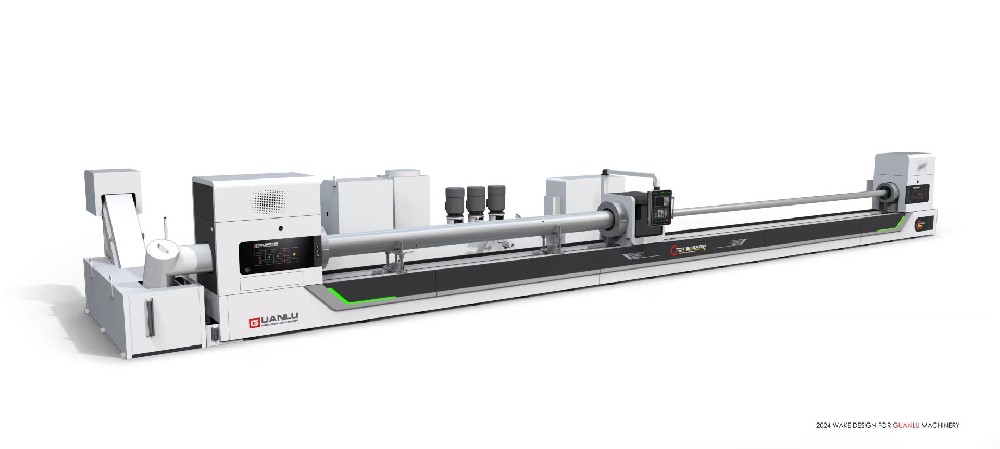

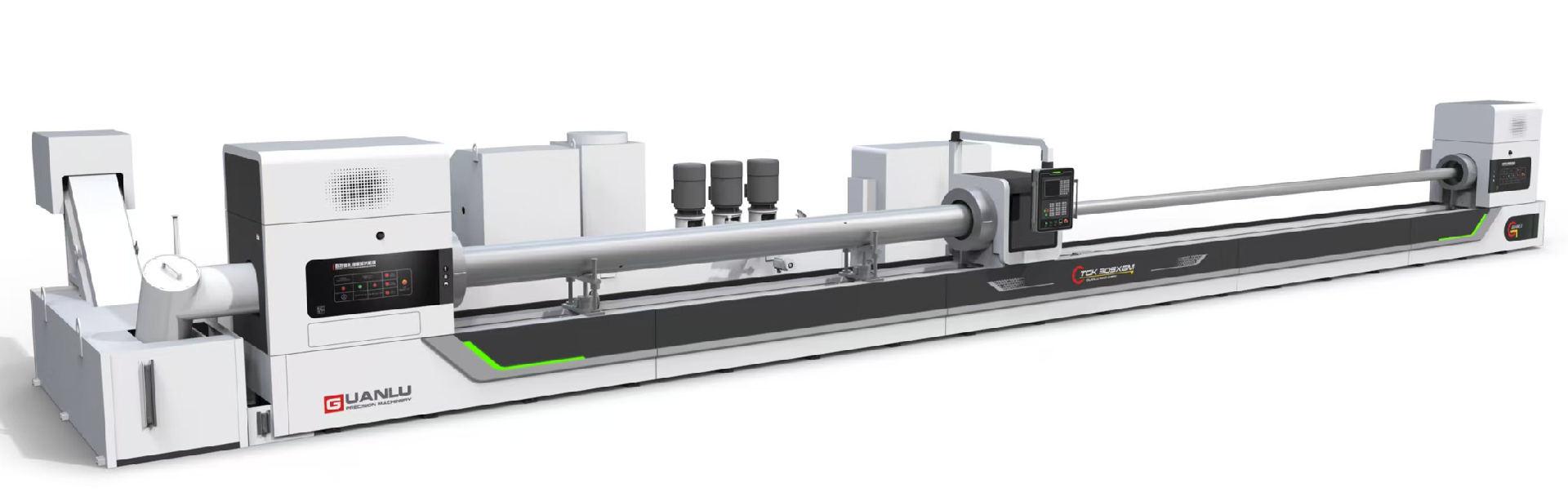

Dezhou Guanlu Precision Machinery Co.,Ltd

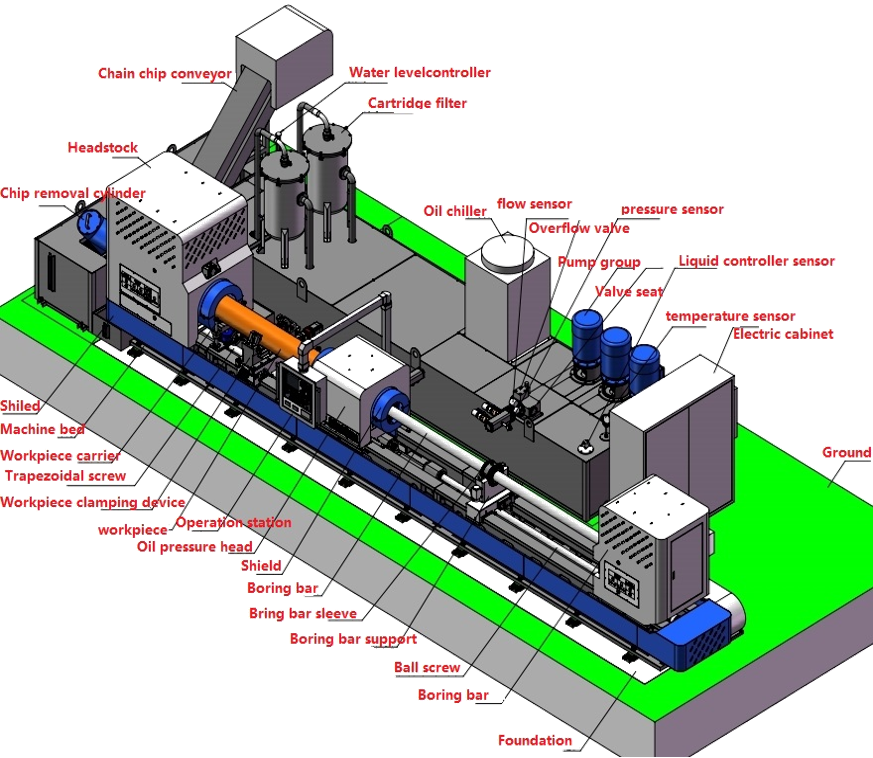

TGK series CNC deep hole skiving roller burnishing machine is suitable for boring, scraping, rolling and combination processing of various hydraulic cylinders,cylinders and other precision pipe fittings. if customer has the requirement of drilling function ,it is also possible. The processing aperture accuracy can reach IT8~IT10, and the surface roughness can reach Ra0.05-0.4μm after rolling.

This machine is the substitution for deep hole drilling and boring machine,it is combined the rough boring、 precise boring and burnishing process together,by using the special SRB tools(forward is for skiving process and backward is for rolling and burnishing process),one time could work out hole roughness to Ra0.05um-Ra0.4um.

CNC controller: Siemens/Fanuc/GSK

SRB machine application industry:hydraulic cylinders,industry cylinders,piston and so on.

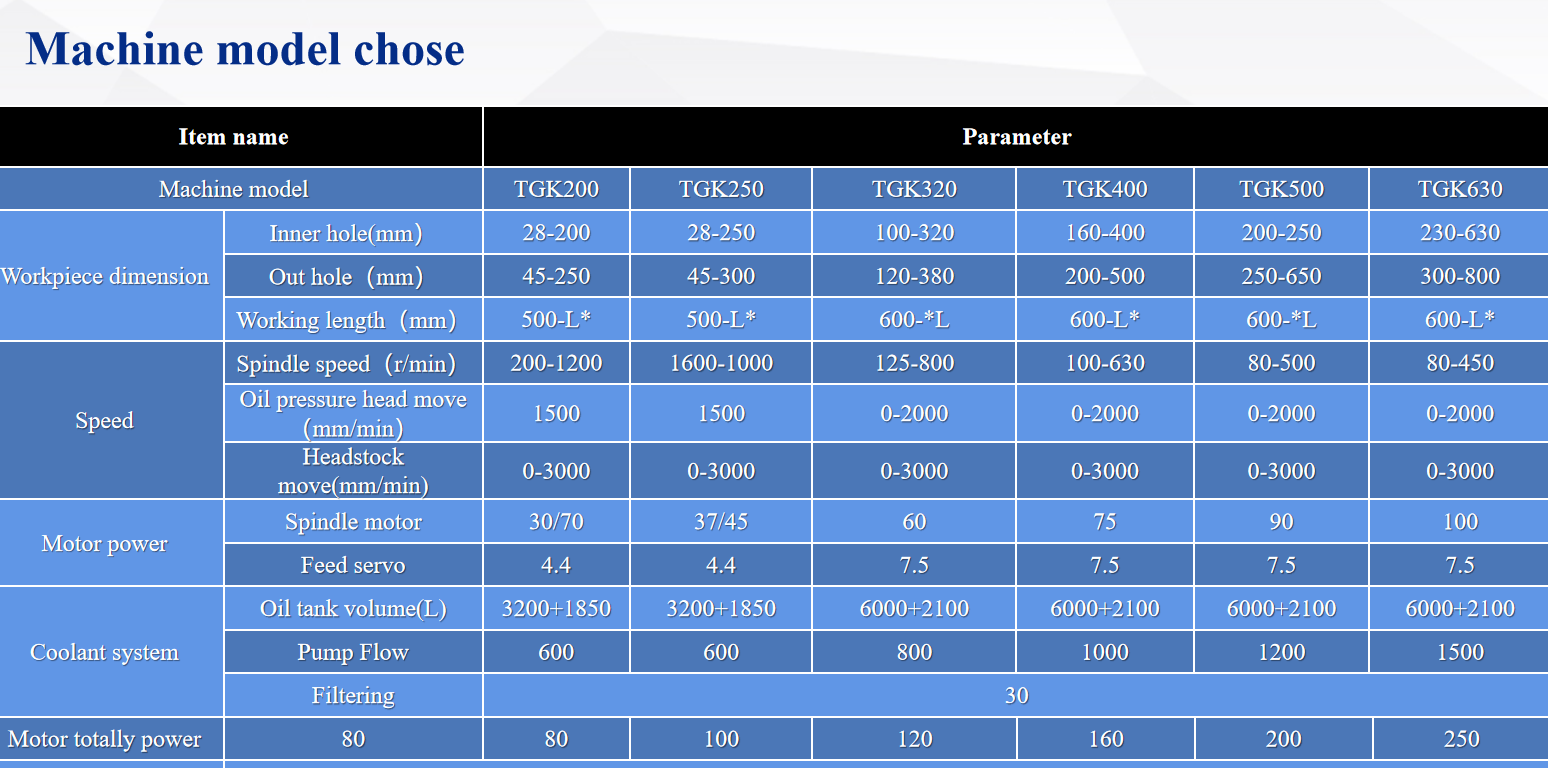

Skiving roller burnishing machine models to selection:

Working range: 30mm-500mm(variously models in between),please advise your hole diameter and we will recommend you the right model.

Working Length: from 500mm to 20000mm(variously models in between)

Guanlu brand SRB machine had two types,one is TGG series,whoes cut value is 5mm for single side,we called it heavy duty SRB machine. The other type is TGK series,whoes cut value is 0.5mm. It is standard type SRB machine.

Function of the SRB machine:(Solid drilling is optional),boring、skiving roller and burnishing.

Skiving roller burnishing machine advantages:

Our independently developed Deep Hole Skiving & Burnishing Machine is a high-efficiency deep hole processing equipment with high power, strong rigidity, wide process range, and excellent efficiency. It is ideal for machining deep holes in cylindrical workpieces like hydraulic oil cylinders.

Combined Boring & Rolling Process – Uses precision boring and high-speed rolling to finish workpieces in one pass.

Efficient Chip Removal – Push boring with Centralized oil supply ensures smooth chip evacuation.

Revolutionary Efficiency – Replaces traditional rough boring, fine boring, and grinding, boosting productivity by 5-10 times.

High Precision – Ensures excellent cylindricity and alignment (cutting/rolling speed: 1 m/min for cold-drawn pipes, 0.3 m/min for hot-rolled pipes).

Multi-Functional – Supports drilling, boring, and rolling, fully replacing deep hole drilling & boring machines.

Advanced structure:Absorbing advanced structure of Japanese and Korean famous brand,exported to several European countries such as France,Germany,Italy.

Applicable for processing the hot-rolled pipes and cold drawn pipes, specially used for hydraulic cylinders industry.

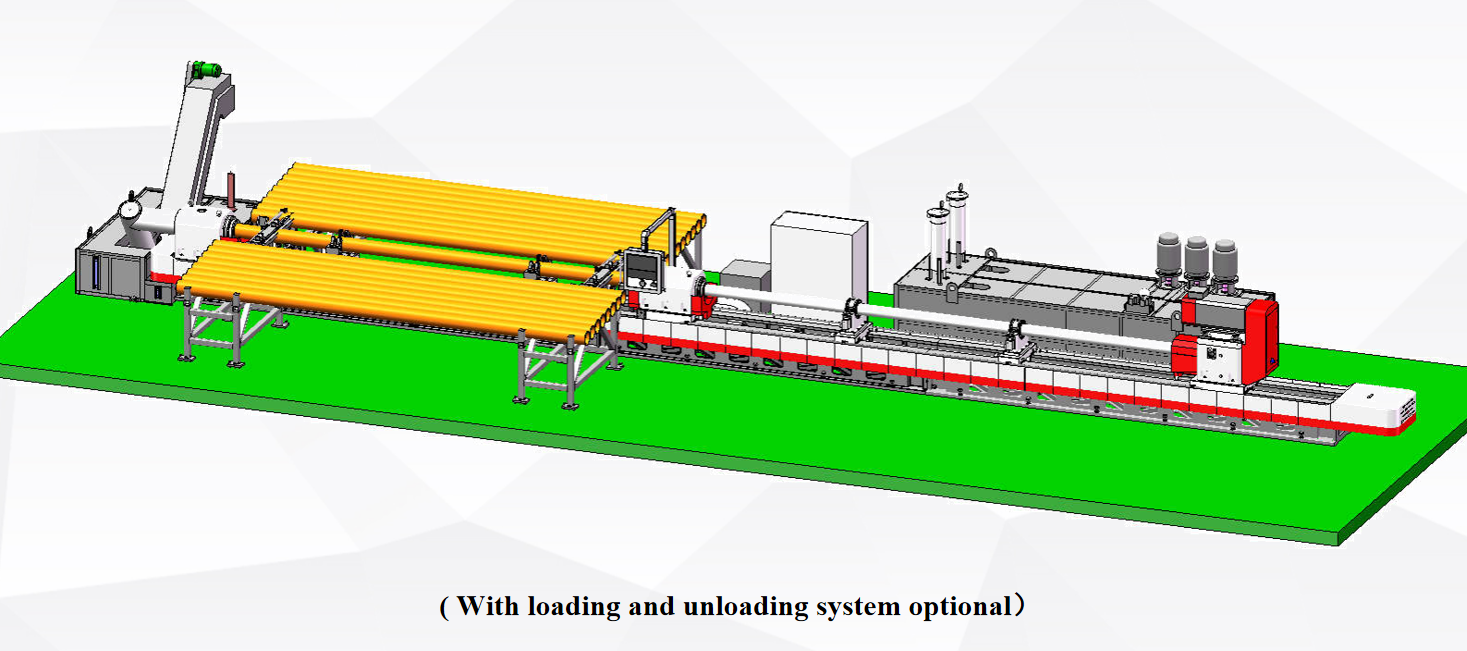

Automation:Auto loading and unloading system is optional.Saving labour cost.

SRB tools is produced by our own factory,it is long life span and with attrative price.

S

Mainly structure of Guanlu SRB machine:

Machine bed:

Machine is with rectangular guide rails, which have been quenched and have high wear resistance; the bed adopts a split structure, which is assembled with high-strength bolts and is positioned with tapered pins.

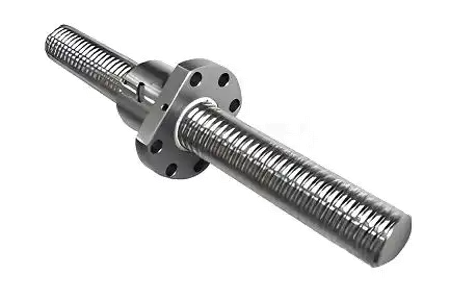

A high-precision ball screw pair is installed at the right end of the bed for the movement of the boring box (Z1 axis). The ball screw pair is used for the feeding of machine, which has the advantages of smooth transmission, high transmission efficiency, and high precision.

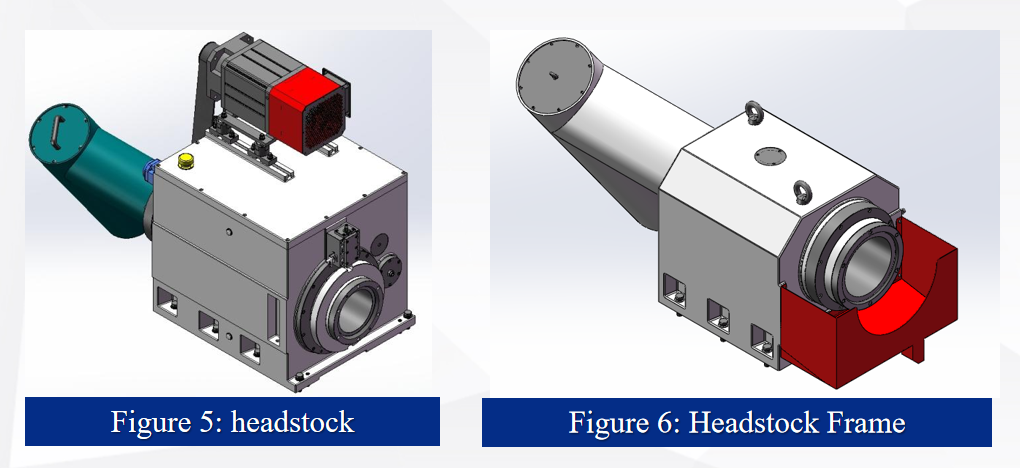

Headstock frame

The head frame is located at the left end of the bed, the hydraulic system drive the spindle inside of head frame to move for tightening the workpiece.

A cone disc and a guide sleeve are installed at the right end of the headstock . The cone disc is used for workpiece positioning and tightening, and the guide sleeve is used to support the cutting tool after machining finished.

A chips removal bucket is installed at the left end of the head frame to transfer the cutting chips and cooling oil into the chips conveyor .

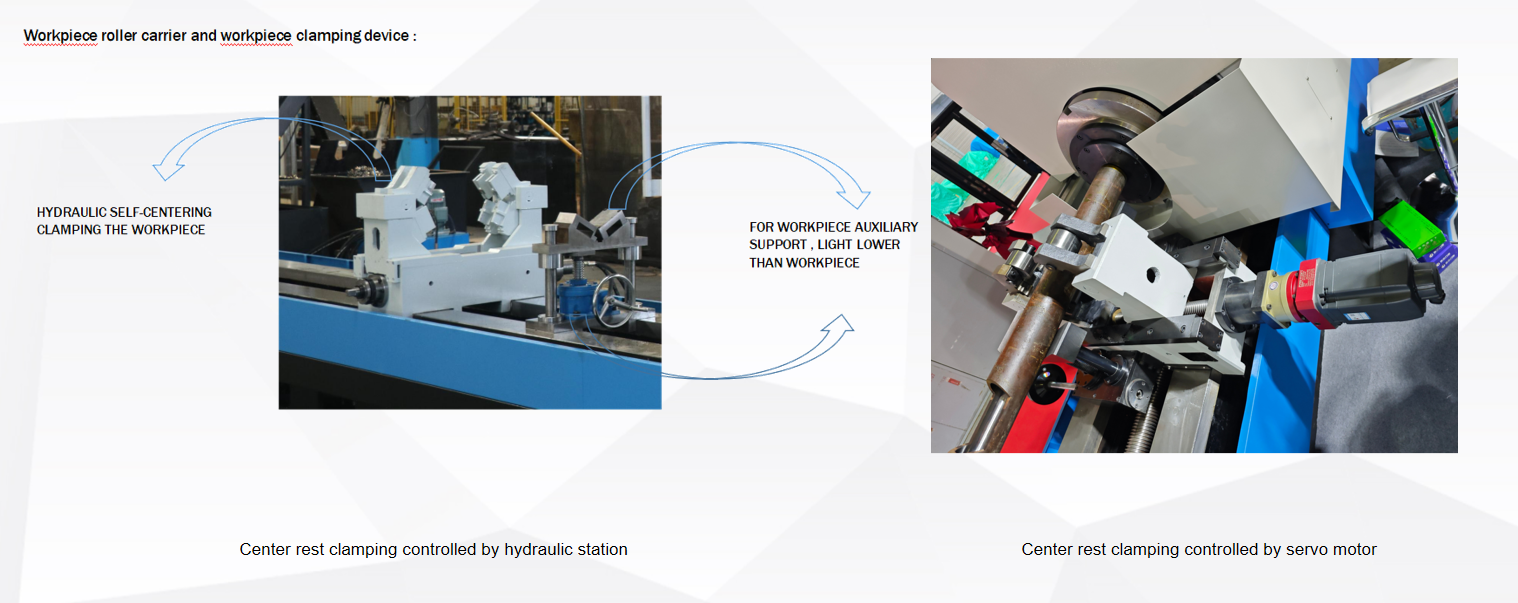

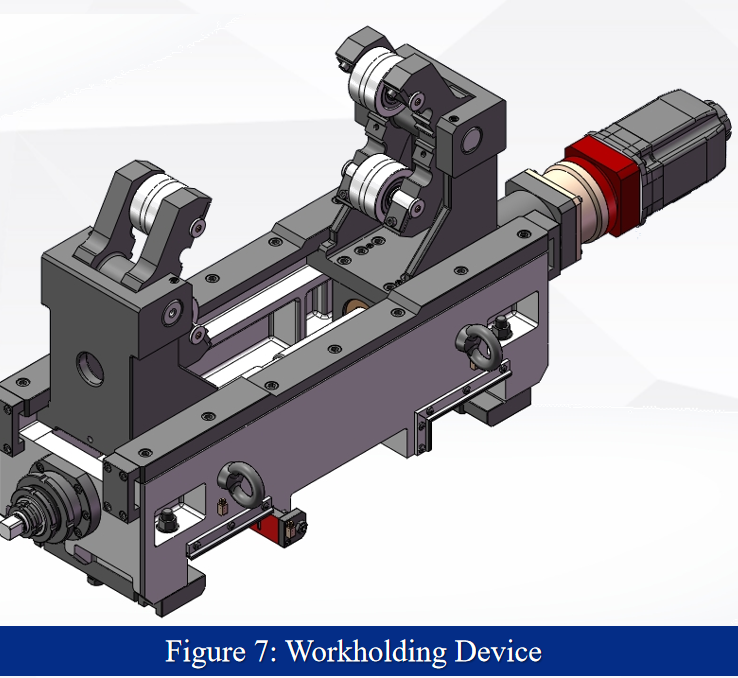

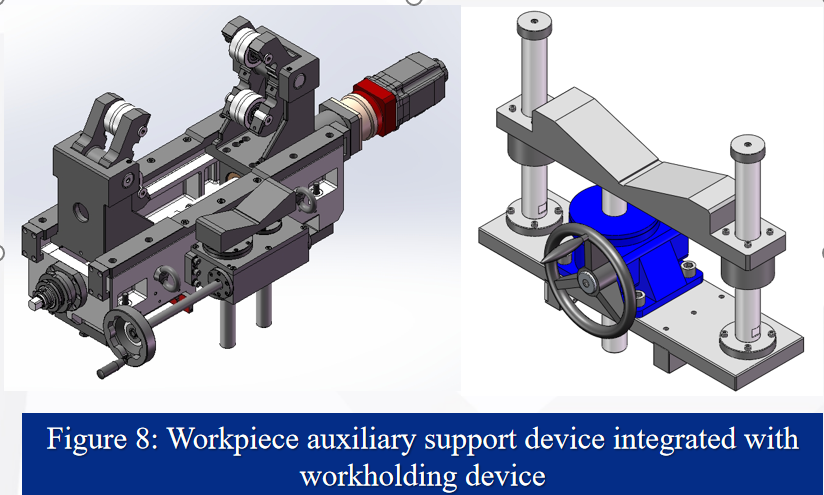

Workpiece carrier and hydraulic clamping device

The workpice carrier is used for auxiliary support of the workpiece, which is convenient for workpiece clamping, and its working position is slightly lower than the workpiece clamping position. The carrier can be raised and lowered manually to meet the support of workpieces with different OD.

The hydraulic clamping device is used for clamping the workpiece .The clamping frame uses the hydraulic motor to clamp the workpiece through the trapezoidal screw, which has the function of self-centering. Workpiece clamping is completed after workpiece tightening, and the clamping sequence can be adjusted manually.

Oil pressure head

The oil pressure head is the core component of the deep hole machines, which is used for guiding the cutting tool , supply cutting oil , supporting boring bars, and workpiece positioning.There is a cone disc mounting in front of the oil pressure head, which is used for positioning and tightening the workpiece. It is combined with the workpiece at a cone angle of 60°. The taper is customized according to the needs of the workpiece. The oil pressure head can be moved to adapt to the processing of workpieces with different length.

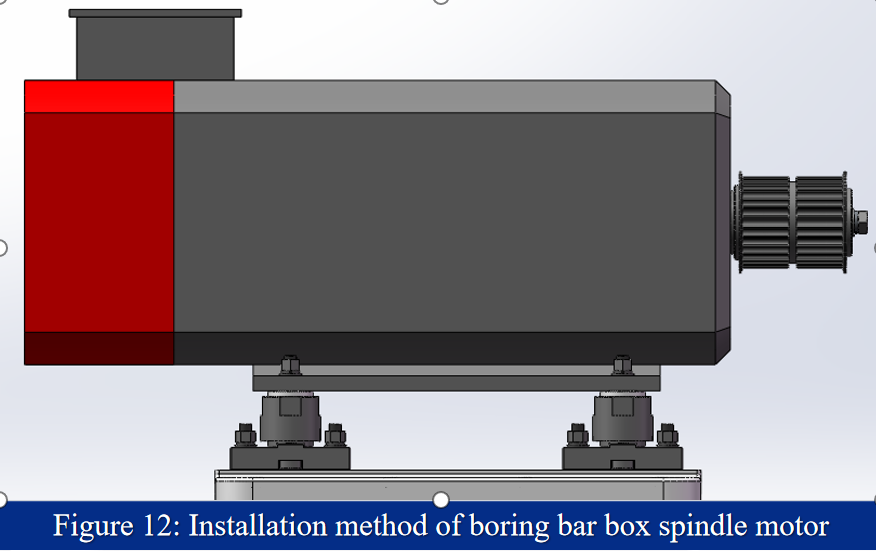

Boring box:

The boring box is fixed on the feeding carriage for driving the tool to rotate and feed. The motor of boring box drives the spindle to rotate through synchronous belt. The front end of the spindle is equipped with a boring bar clamping sleeve for clamping the boring bar.

The bearing of boring box is lubricated by an independent lubrication system to circulate the lubricating oil.

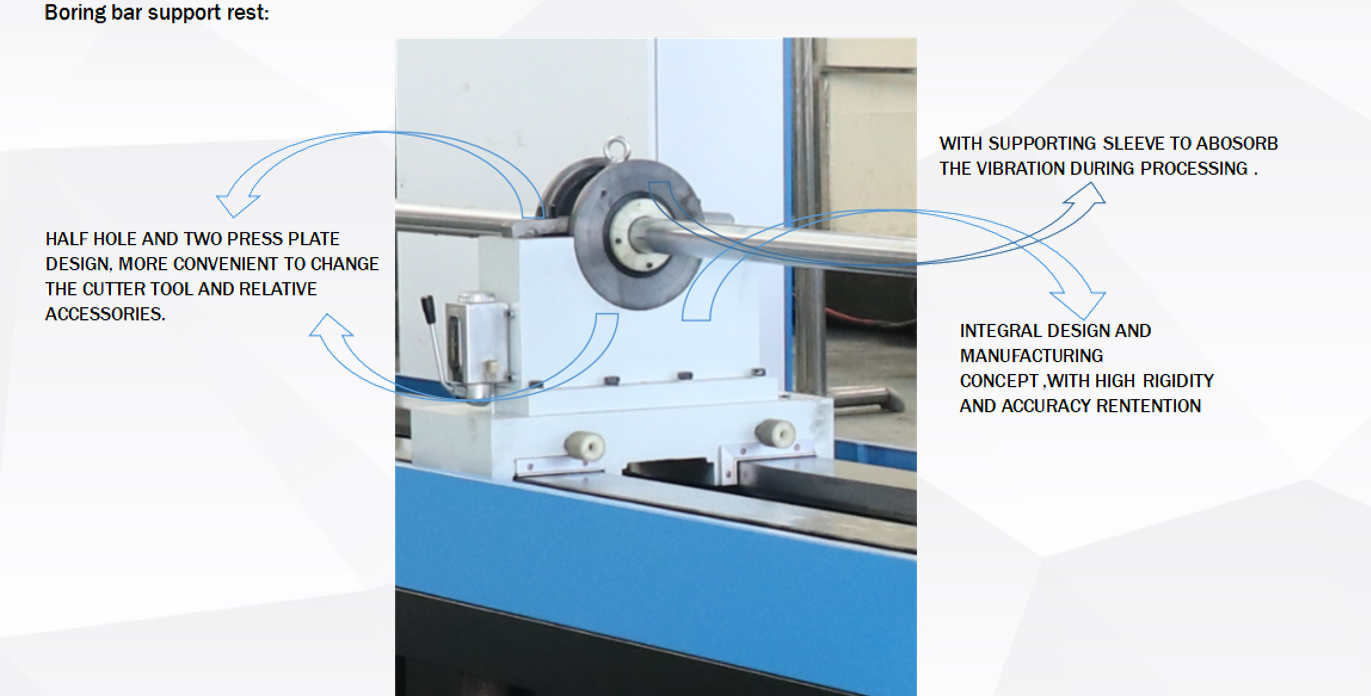

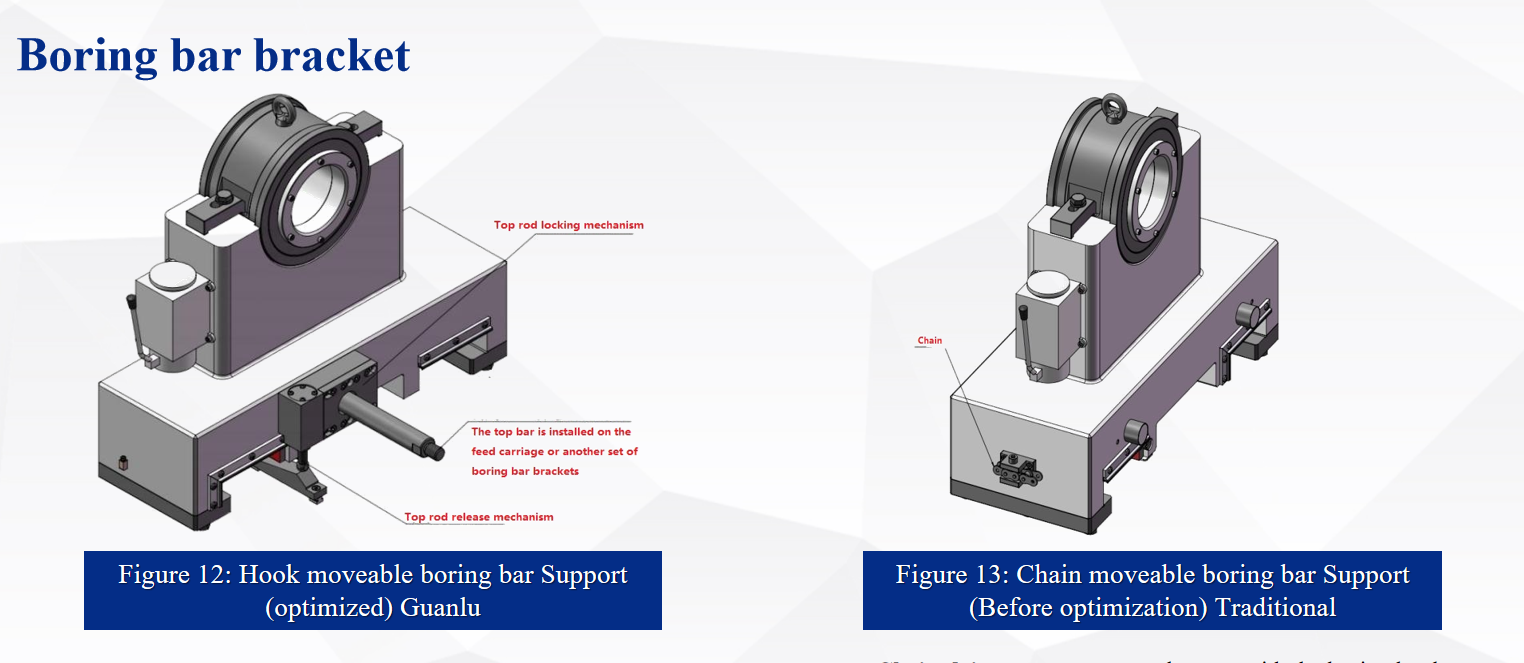

Boring bar support rest:

It is used to support the boring bar, and a support sleeve is mounted on it, which can absorb the impact and jitter generated during the processing.

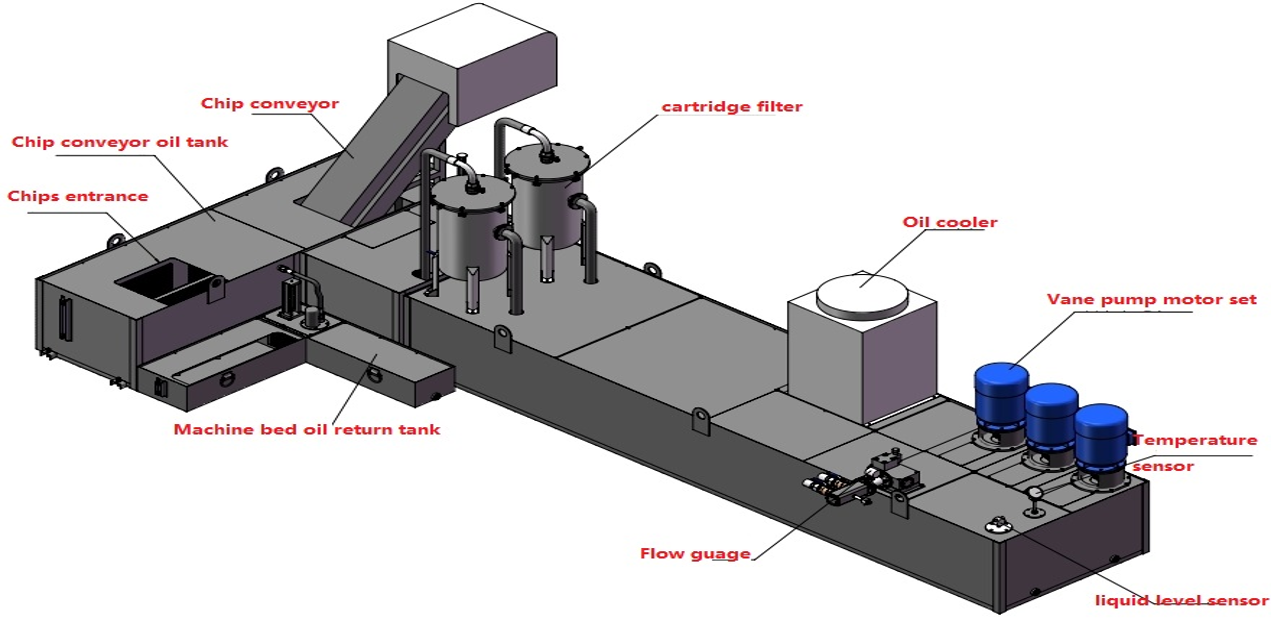

Coolant system:

The main function of the cooling system is to use the circulating liquid medium to lubricate and cool the cutting area and remove the cutting chips. The cooling system adopts an above-ground oil tank structure. The cooling oil take away cutting chips by the chips conveyor and then filtered through a three-stage filter (rough filter)-magnetic filter-cloth bag fine filter.

Advantages of TGK25 series CNC deep hole skiving and Roller burnishing machine

The overall layout of the machine tool is scientific and reasonable, and the overall appearance is simple and beautiful. The host sheet metal protection adopts plastic spray treatment.

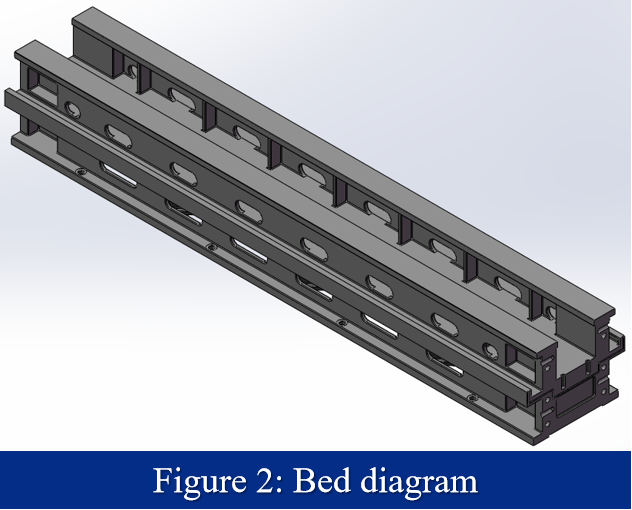

SRB machine bed

Total width: 800mm Guide rail span: 650mm

Single rail dimensions: 160mm (width) × 50mm (thickness)

Design optimized by finite element analysis for: Lightweight and rigid structure ,High precision performance

Custom-designed for optimal performance

Large central installation space

"W-shaped" internal stiffeners for enhanced rigidity

Middle plane slightly elevated above side oil grooves

Long round holes on both sides for efficient oil return

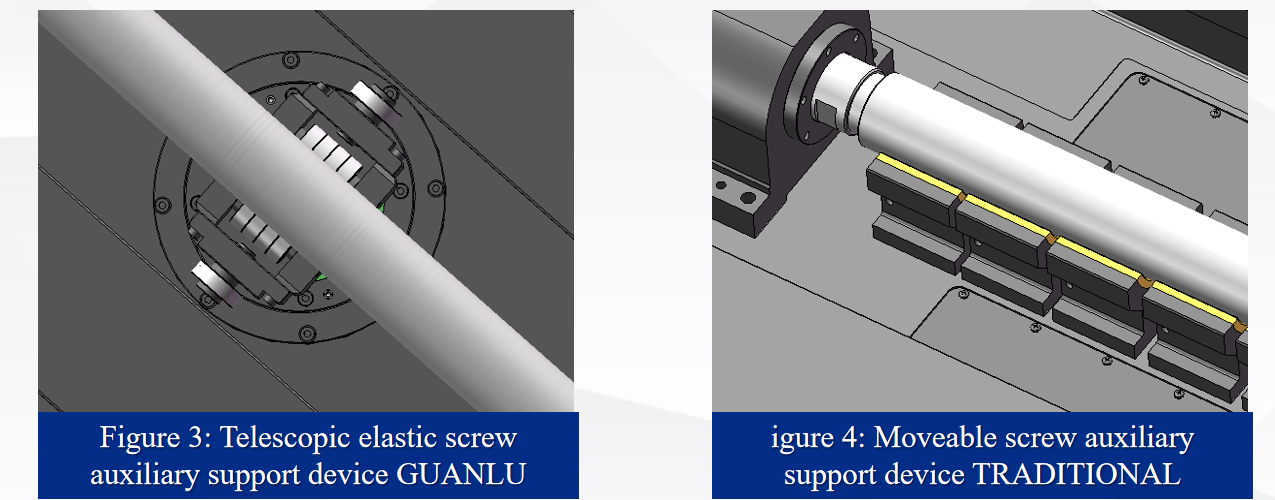

SRB machine Lead screw auxiliary support device

Telescopic elastic Guanlu design (Fig.3) vs. movable support traditional (Fig.4)

Zero-gap contact with screw (spring-loaded roller)

High rigidity support without increasing screw's invalid length

Requires custom bed design for large central installation space

Lead screw and its installation method

Boring bar box feed: Φ80mm ball screw pair (Transmission smoothy)

Oil pressure head movement: Φ80mm trapezoidal screw pair (Auto lock function)

Bearing system:Four sets of special precision rolling bearings at each screw end

Ensures high rotational accuracy, heavy axial load capacity, and extended service life

Headstock (equipped with double rotating machine tool) and head frame (equipped with single rotating machine tool)

Both the spindle of the headstock and the headstock frame adopt largehole structure, which has good chip removal ability. Because the headstock dopts a large hole structure, the bearing specifications are large and has strong rigidity.

Workholding device

Servo motor-driven via trapezoidal screw (self-centering effect)

Adjustable speed & clamping force for flexible operation

Universal compatibility: Works for both rotating & non-rotating workpieces

Modular design: Function conversion possible by replacing modules

Workpiece auxiliary supporting device

Innovative worm gear & screw lifting mechanism for smooth operation

High reduction ratio transmission ensures precise control

Side-mounted handwheel for easy assembly operation is relatively light

Workpiece Compatibility: Supports outer diameters from Φ50mm to Φ400mm

Large Bracket Travel: Accommodates significant workpiece size variations

Custom Bed Design: Requires expanded central installation space for optimal functionality

Modular design – integrates auxiliary support and clamping functions

Independent operation for flexible configuration

Adaptable to machine specs and workpiece requirements

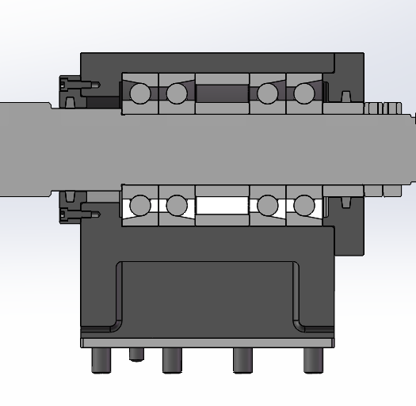

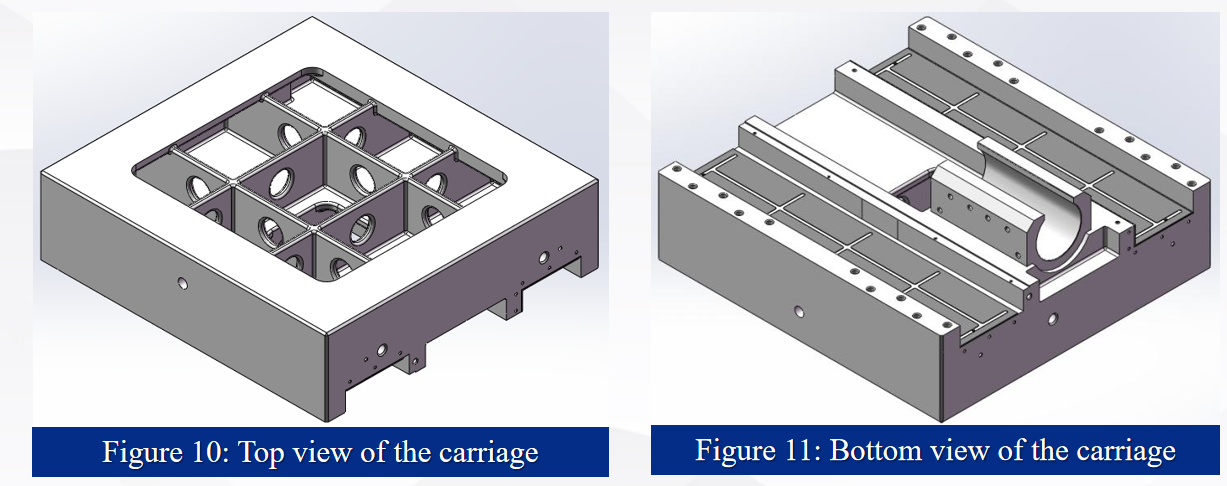

Carriage:

Carriage Design

Feed carriage (boring bar box movement) & Oil pressure moving carriage – similar strong structures.

High Rigidity & Precision

Integrated nut seat & carriage design ensures superior rigidity and long-term accuracy retention.

Advanced Guide Rail Coating Technology

Anti-friction injection-molded coating provides:

Excellent wear resistance

Low compression ratio

Wide working temperature range

Self-lubricating properties (special embedded materials)

Low friction coefficient & anti-crawling performance

Main motor installation

Multi-directional adjustment (left, right, up, down) for precise alignment of synchronous pulleys.

Improves pulley positioning accuracy, reducing synchronous belt noise.

Extends belt lifespan by ensuring optimal tension and alignment.

Boring bar bracket

Hook design ensures synchronized movement with the boring box during retraction.

Automatic disengagement when reaching the set position.

Chain-driven movement – advances with the boring bar box.

Chain tangling risk – may knot when stacked during forward motion.

Backward motion risk– pulling a knotted chain can cause breakage.

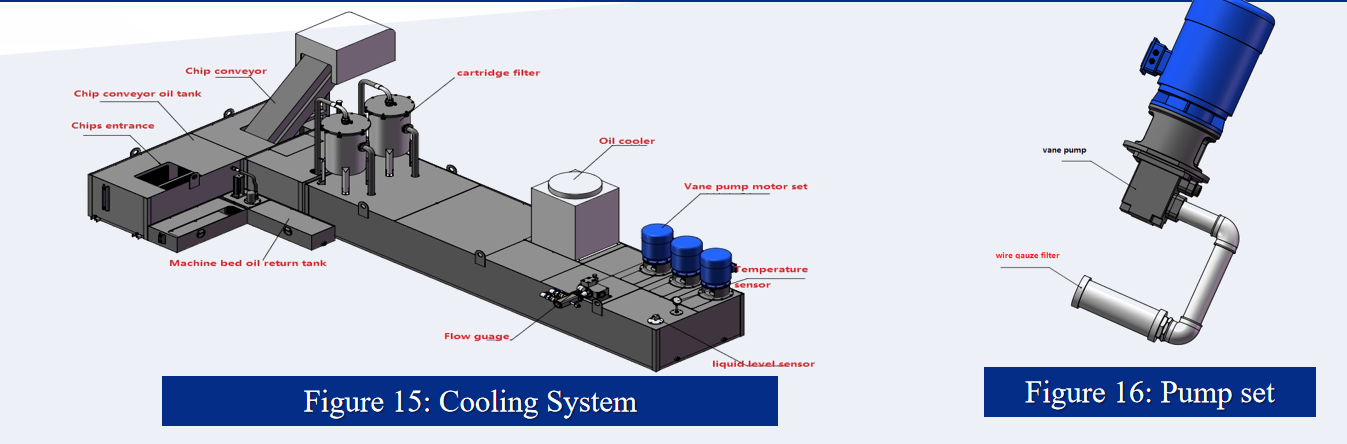

Cooling system

Main Function:Circulates liquid medium to lubricate, cool the cutting area, and remove chips.

Structure & Filtration

Above-ground oil tank design.

3-stage filtration process:

Filter screen (coarse) → Magnetic filtration → Filter element (fine, 50 μm accuracy).

Chip conveyor removes iron filings before filtration.

System Components

3 main parts: Bed oil return tank, chip remover, and cooling oil tank.

Total oil capacity: ~8000L (helps control oil temperature rise).

Filter element (lower loss vs. filter paper tape).

Monitoring & Control

Equipped with pressure, flow, level, and temperature sensors.

Display instruments mounted on the control panel for easy monitoring

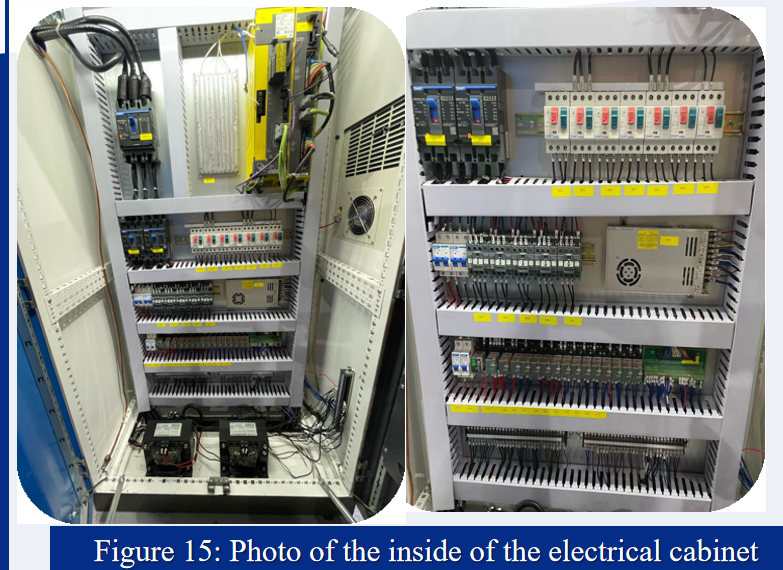

Electrical cabinet

Electric cabinet Structure

American Rital design

Excellent ventilation, heat dissipation, and dustproof performance

Components & Reliability

Equipped with an air conditioner

Low-voltage electrical parts: Schneider brand for stable operation in hot weather

Connection Machine linked via aviation plug

Details about Guanlu and Guanlu Brand deep hole honing machine.

Dezhou Guanlu Precision Machinery Co.,Ltd,is founded in year 2011,we are the most famous factory in my local to manufacture deep hole drilling machines,deep hole skiving roller burnishing machines.. My city Dezhou is the production base of deep hole machines in China.

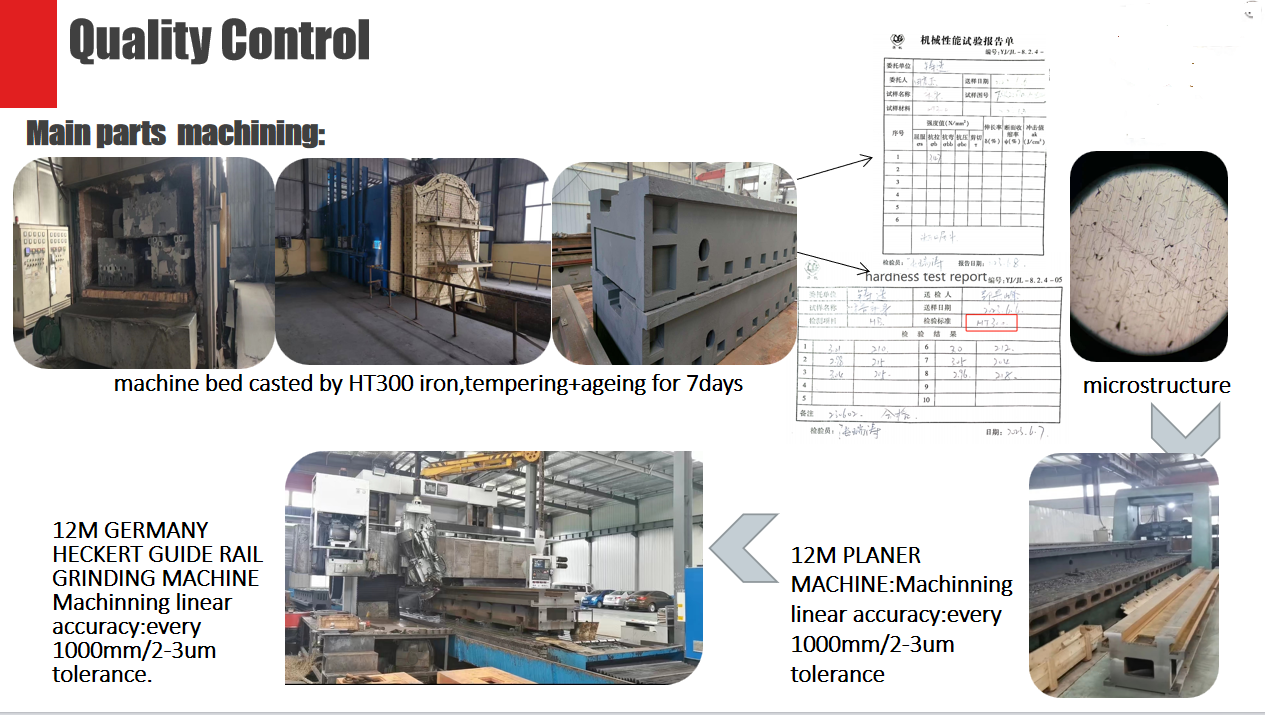

We have our own strongly machining facilite, Germany brand Heckert guide grinder,Japanese SNK five face milling center ,chinese most famous planner,VMC,Lathes,box boring machine,milling machine and so on. With these good machning facility,we could be able to manufacture the best quality and best accuracy deep hole machines,under proper management system,we could orgnize production properly,our delivery of machines are stable and in time,we also have some regular models stocks.

Our deep hole has been exported to more than 50 countries and gained good reputation and fame. We improved our quality and structure day by day.

DZ Guanlu FACTORY advantages compared with other competitors:

Our city is the production base of deep hole drilling and boring machines. Among these local competitors,our company is the first choice once clients has visited us and saw our deep hole machines. we have the absulately advantages than others.

Big workshops and Big factory: we have four workshops,one commercial office building and totally 70000square meters working area.

One workshop is 10000square meters.

Two other two is 13000 square meters.

One is 8000 square meters.

All workshops are heavy duty,crane is 32tons,height is 14meters.

Floor foundation loading is 400tons.

SO we have capacity to manufacture heavy duty deep hole drilling machines.

Strong machining facilities. Good quality and good accuracy machines are maufactured by good machining machines and skilled workers. We have two sets Germany brand Heckert guide grinder. The guide rail of the deep hole machines are the most important part,it decides the accuracy of machines. after ground by our grinder,the surface of the machine bed likes mirror. Our Japanese brand SNK five face milling machine will work on all the box parts of the BTA drilling machine. Chinee famous brand horizontal boring machine,planning machine,VMC machines,CNC lathe machines.

Strong machining facilities. Good quality and good accuracy machines are maufactured by good machining machines and skilled workers. We have two sets Germany brand Heckert guide grinder. The guide rail of the deep hole machines are the most important part,it decides the accuracy of machines. after ground by our grinder,the surface of the machine bed likes mirror. Our Japanese brand SNK five face milling machine will work on all the box parts of the BTA drilling machine. Chinee famous brand horizontal boring machine,planning machine,VMC machines,CNC lathe machines.

Most famous technicians. Our company has the most professional technicians. Six engineers totally. All of them had worked in this field for more than 15years. They are full of experience,can design the deep hole machines according to customers request.

Skilled worker teams. Nowadays,it is not easy to hire workers. Especially skilled workers. But our company has special management system to keep these skilled workers. So all of our machines are assembled by skilled workers.

Quality control system,from machine design,parts purchase,parts machining ,machine assemble,machine test running,machine packing,all the process,we have inspection system to warranty the deep hole machine quality.

We use ERP to manage the whole company running system. Every purchase parts,produced parts,machined parts are inspected seriously, all the asseble process are inspected by our inspector.

Our inspection instruments: Renishao laser inferferometer,laser linear meter,roughness meter,time aging meter and so on. ALl of our instruments are inspected every year.

We are the only deep hole machine manufactuer that can sign quality assurance contract and after sale service contract ,so all customer will rest assured after buy our machines.

In time after sale service:

Guanlu has been attended many international exhibitions:

FAQ time:

Q:Are you real SRB manufacturer?

A:Yes,we are 100% real factory manufacturer,who could provide you reliable and eternal after sale service. we are the REAL factory directly sale. VIDEO CALLL ANY TIME.

Q:Can you design the deep hole drilling machines according to our job and our special requirements?

A:Yes,we always accept the customs designed orders.

Q:How many countries have you export,after sale service available?

A:We have exported to more than 50 countries until this year. we have agent in Russia,India,France,Canada,Mexcio and Brail....

Q:What is your SRB machines warranty ?

A:Normally,our SRB series machines warranty is for one year,if longer warranty request,we could discuss.

Q:What is your machines lead time?

A:For regular skiving roller burnishing machines,we have semi machines,which we could build the machine within one month. for the customerized machine,it depends on the design time,about 4month orso.

Q:Will you test the machine before shipment?

A:Yes,no matter the client will come to inspect the deep machine before shipment or not,we will test two or three pieces jobs ,in case the machine has problems,we could solve it before shipment.

Full line machines Guanlu provide:

BTA deep hole drilling mahine,deep hole honing machine,deep hole skiving roller burnishing machine,deep hole gun drilling machine,three axi/six axis deep hole rilling machine,CNC large lathe,CNC heavy duty lathe,CNC pipe threading machine,slant bed lathe.

Deephole machine package when shipping:

Machines will be packed by plastic film,all the small parts are packed into wooden box,while fragile parts such as panels are well packed and protected.Parts inside containers will be well fasten by irons and belts.

More information Contact now:

Susan Lee

Mobile/wechat/whatsapp:+8615165964868

Mail: dzguanlu@dzguanlu.com

website:www.dzgljc.com