Dezhou Guanlu Precision Machinery Co.,Ltd

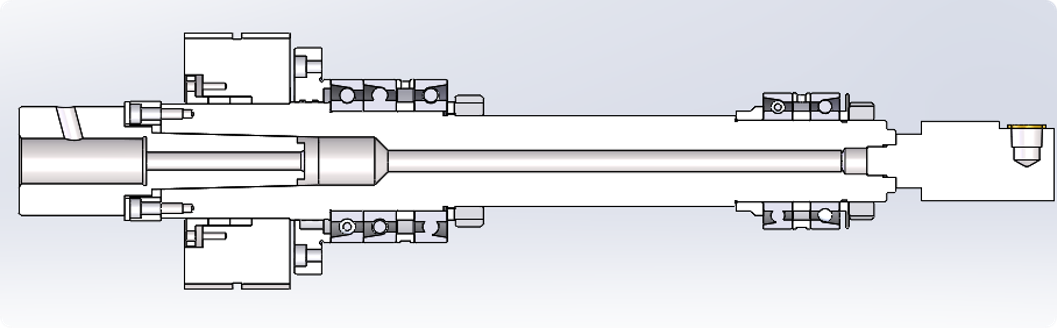

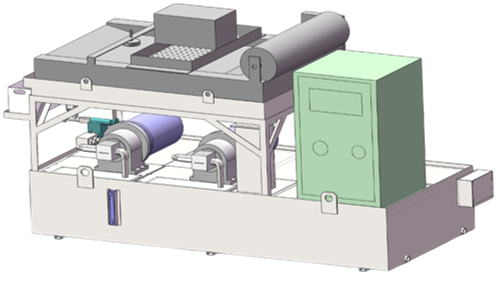

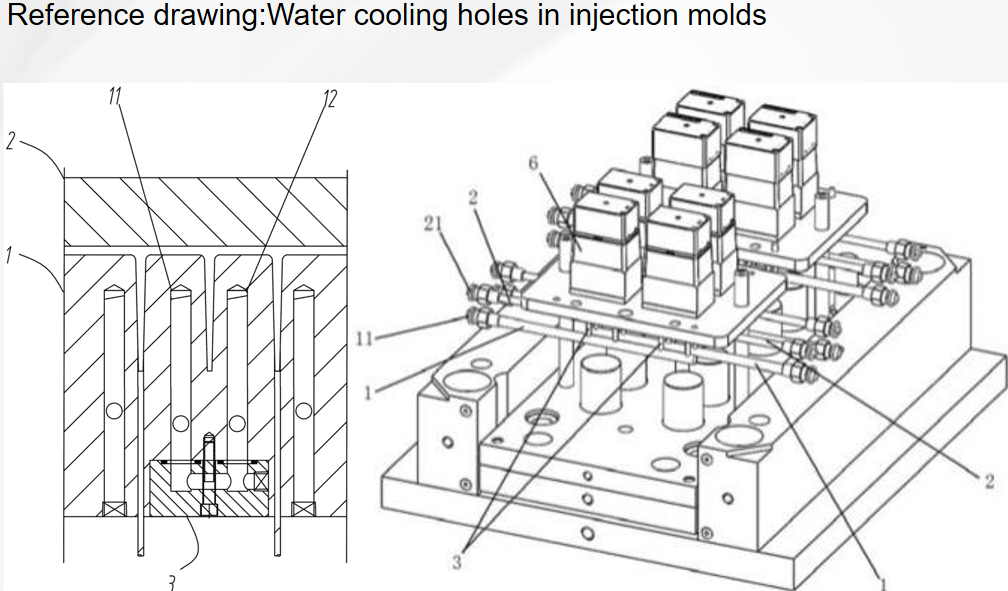

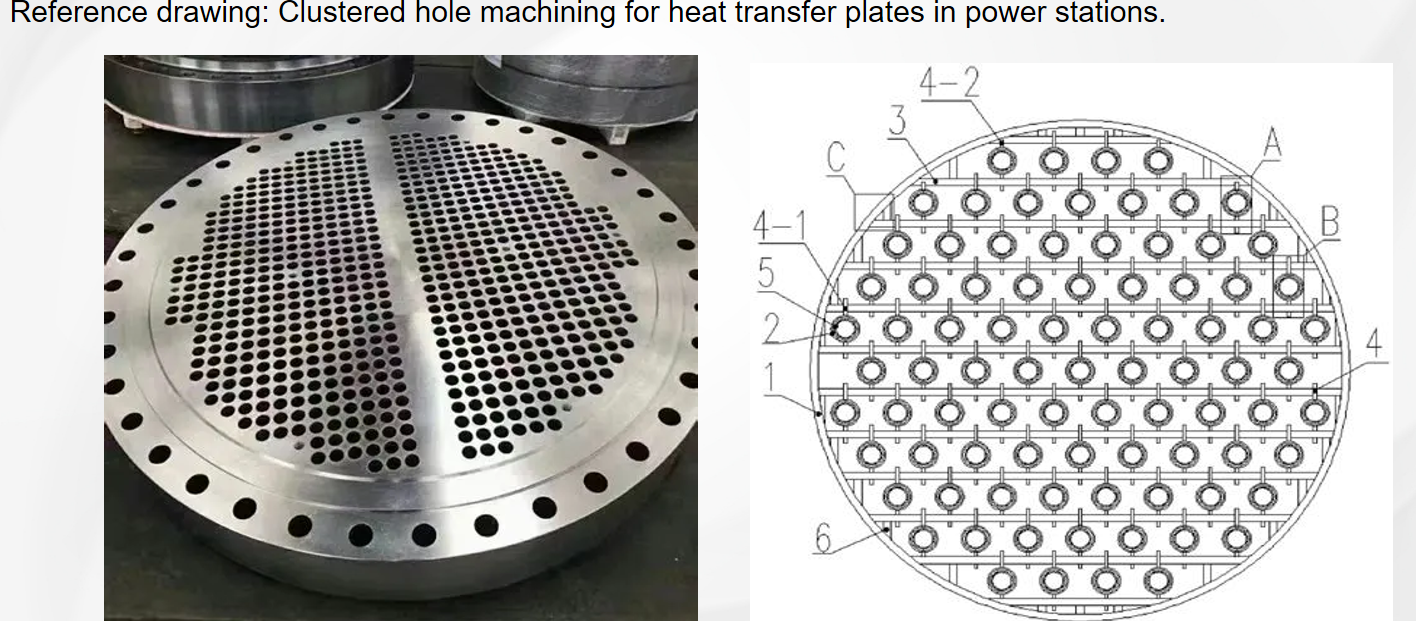

Three axis gun drilling machine is used for drilling the coordinate holes on the job.It can drill straight hole,taper hole,through hole,blind hole and step hole.

There are six servo axis on the machine:

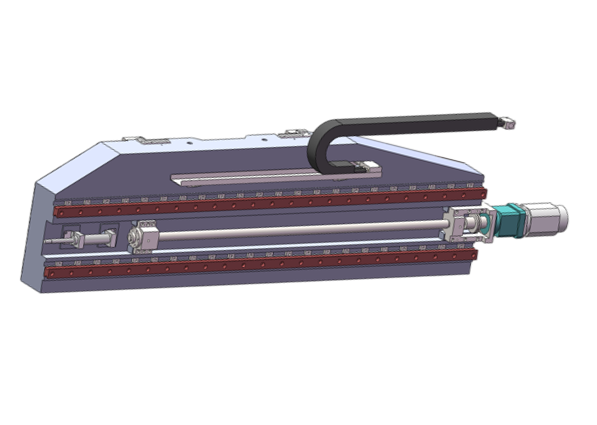

X axis:drive job move in horizontally,roller linear guide rail. CNC control.

Yaxis:drive job move in vertically,roller linear guide rail. CNC control. Block balanced.

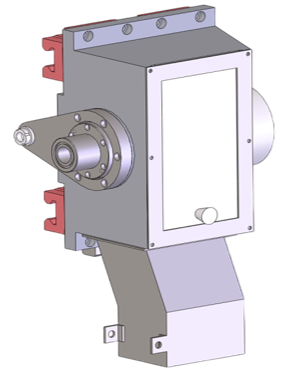

Z axis:drive cutting tool infeeding,roller linear guide rail,CNC control. W axis:Control the distance between pillar and working table;double rectangle slide guide rail.

CNC control.

A axis:Control the cutting tool swing angle;slide guiding rail,close loop control.

B axis:control the job index,CNC control.

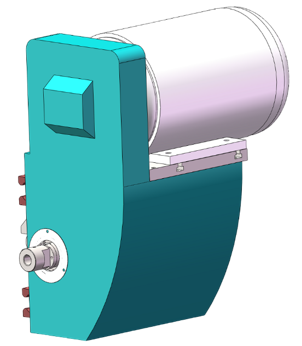

Drill box: main spindle maxiumum speed 6000r/min,single spindle structure.

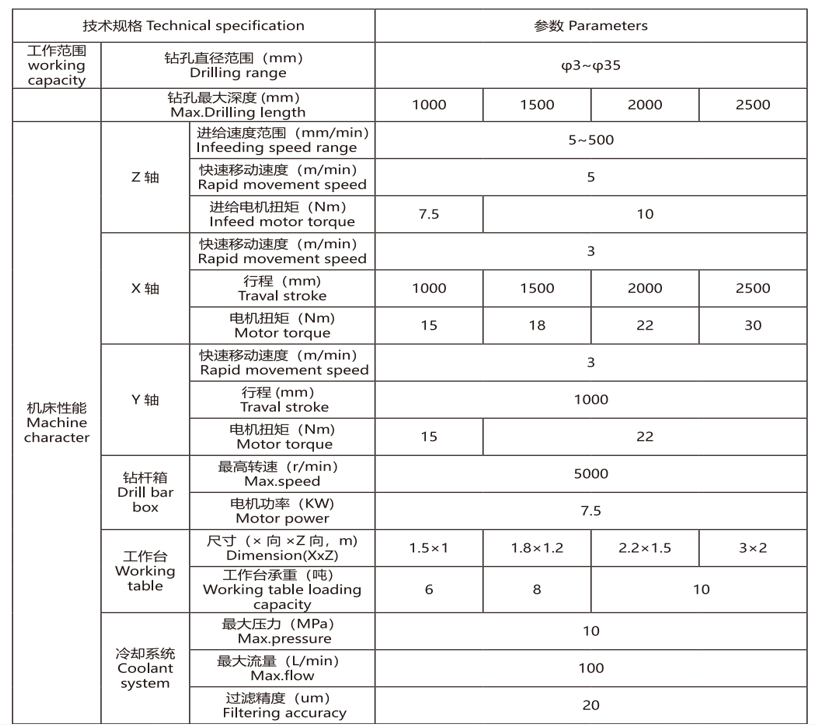

Dezhou Guanlu three axis deep hole drilling machine capacity:

both gundrilling and BTA drilling function.

Gun Drilling: Ø3-40mm,BTA: Ø18-102mm (BTA optional configuration)

Max. machining depth:4000mm

Length-to-Diameter Ratio ≥100:1;

Function: drilling(milling or tapping function is optional)

Advantages of GUANLY Coordinate Deep Hole Drilling machine

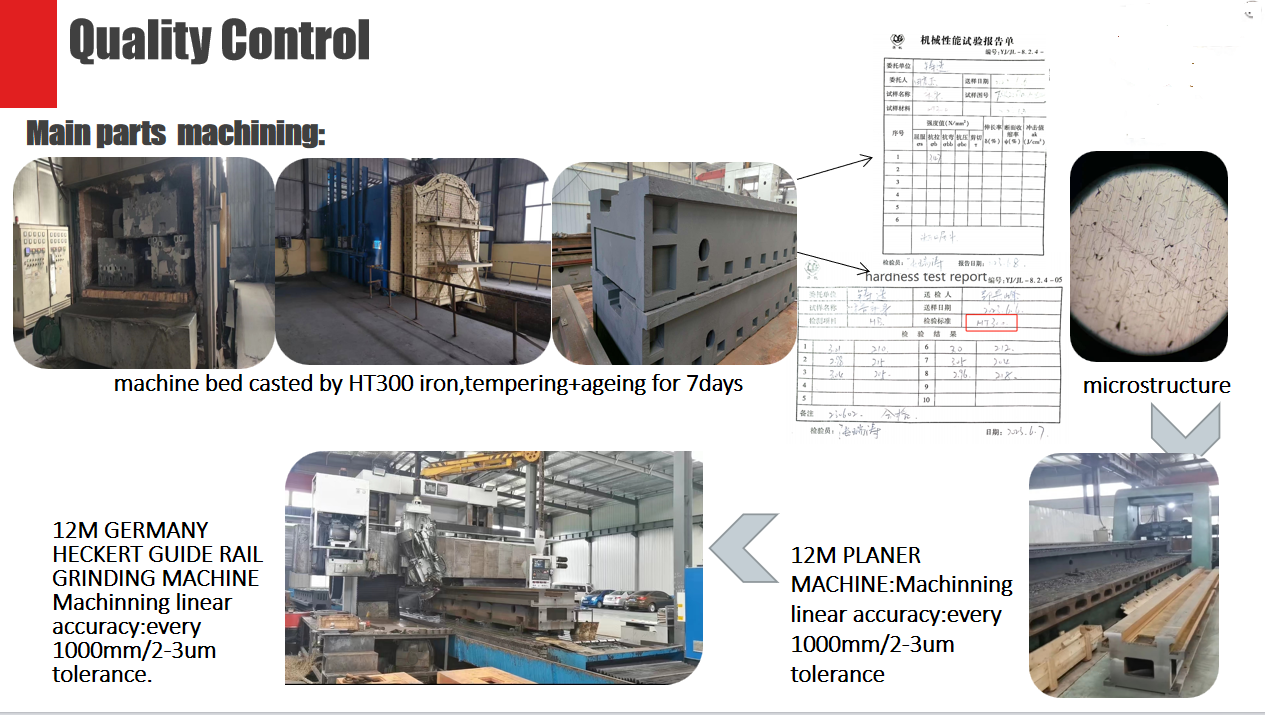

The bed, column, worktable and slide table are all cast from high-quality cast iron resin sand and have undergone two aging treatments to eliminate internal stress. The arrangement of the reinforcing rib plates is reasonable. Therefore, it has the advantages of high precision, long service life, strong rigidity and good precision retention.

The main shaft bearing of the drill pipe box adopts high-precision angular contact ball bearings.

The rear end of the spindle is equipped with a Dubolin rotary joint from the United States to provide a stable cooling supply for deep hole processing and ensure the normal cutting of the machine tool.

The main shaft drive is placed at the front, which is conducive to protecting the main motor and facilitating tool changing.

The X, Y and Z axes all adopt a structure where servo motors drive ball screws,featuring high transmission efficiency, high positioning accuracy and high repeat positioning. The lead screw bearings adopt high-precision angular contact ball bearingsThe lead screw bearings adopt high-precision angular contact ball bearings.

The feed system adopts rolling linear guides to enhance the response speed and sensitivity of the CNC control system,achieving high positioning accuracy and repeat positioning accuracy.

The left end of the guide frame is equipped with a guide sleeve, which serves to guide, seal and remove chips from the drill bit. A drill pipe support sleeve is assembled at the right end of the guide frame to provide support for the drill pipe, which can enhance the rigidity of the drill pipe. The guide frame as a whole moves axially under the control of the pneumatic system.

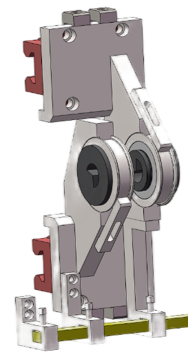

Drill bar support, used to support the tool bar, reduce the vibration of the tool bar, ensure uniform force distribution on the tool and stable feed.

The guide rails for moving the drill pipe support adopt rolling linear guide rails, which move quickly and flexibly.

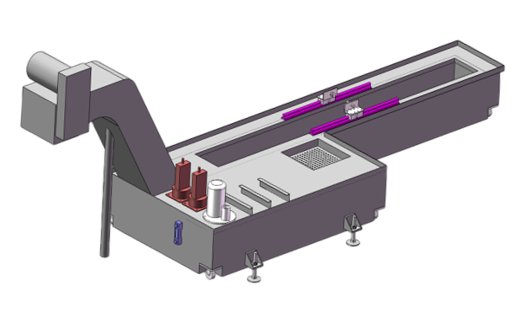

Cooling system: It is mainly composed of a high-pressure pump set, a chain plate chip conveyor, an oil cooler, a filtration device, etc.

The pressure, liquid level, oil temperature and flow rate of the cutting oil can be digitally displayed on the control station.

Multiple CNC control systems: GSK,FANUC,SIEMENS

The lubrication of the linear guide rail slider, lead screw nut and main shaft used for the movemen of the drill pipe box is uniformly supplied with oil at regular intervals and in fixed quantities by the automatic lubrication pump station. And it has a low liquid level alarm function.

The machine tool is protected by sliding protective doors, which facilitate the loading and unloading of workpieces.The leak-proof design of the sheet metal structure has improved the quality of the working environment.

Dezhou Guanlu three axis deep hole drilling machine capacity:Our three axis deephole drilling machine has gundrilling and BTA drilling function. It has two drilling system,Gun Drilling: Ø3-40mm,BTA: Ø18-102mm (BTA optional configuration)

Max. machining depth:4000mm

Length-to-Diameter Ratio ≥100:1;

Standard accessories:①auto Chip conveyor and cart②Air conditioner for electrical box③Coolant pump④Steady rest for tools⑤Working light⑥Tool box⑦English operation manual

Optional accessories:①Auto chips conveyor②Drum type paper filter③Guide bush④Steady rest guide bush⑤Gundrill resharping grinding machine⑥Oil centrifugal extractor⑦Transformer⑧Coolant chiller⑨Full cover safety guard⑩.Index working table

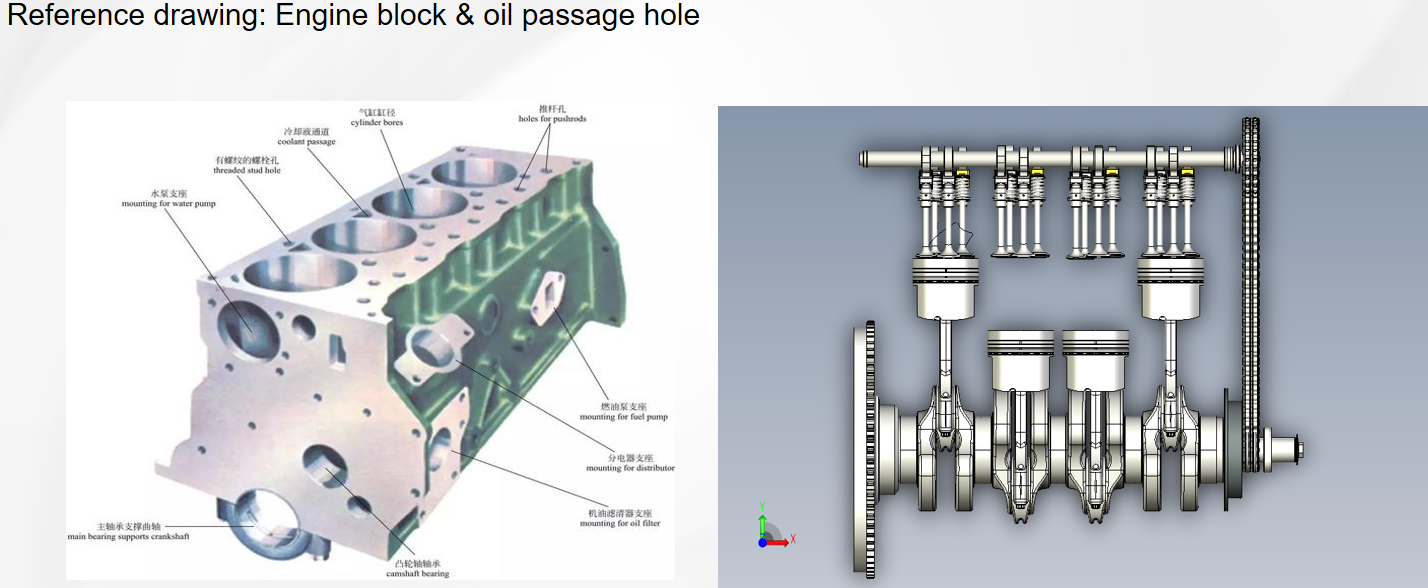

Three axis deep hole drilling machine application:moulds industry and pallet die industry.

3D deep hole drilling/gun drilling machine application fields:

CNC Gun drilling and BTA drilling combined machine for work job.

The drilling diameter range is 10-102mm,

max. machining depth is 3000mm.

CNC three axis gun drilling machine for graphite:

Three axis four spindle deep hole drilling machine for bottle mold drilling:

Three axis deep hole drilling machine for optical fiber industry:

More applications for the 3D mold drilling machine:

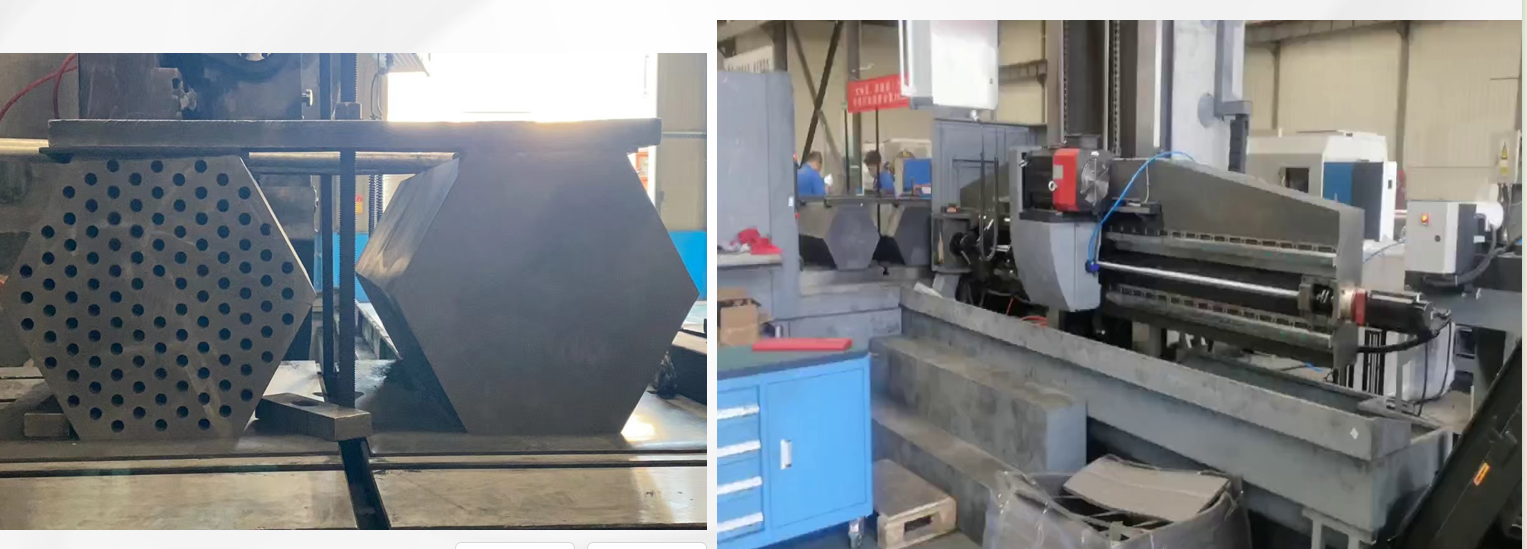

DZ Guanlu FACTORY advantages compared with other competitors:Our city is the production base of deep hole drilling and boring machines. Among these local competitors,our company is the first choice once clients has visited us and saw our deep hole machines. we have the absulately advantages than others.

Big workshops and Big factory: we have four workshops,one commercial office building and totally 70000square meters working area.

One workshop is 10000square meters.

Two other workshop are 13000 square meters.

One is 8000 square meters.

All workshops are heavy duty,crane is 32tons,height is 14meters.

Floor foundation loading is 400tons.

SO we have capacity to manufacture heavy duty deep hole drilling machines.

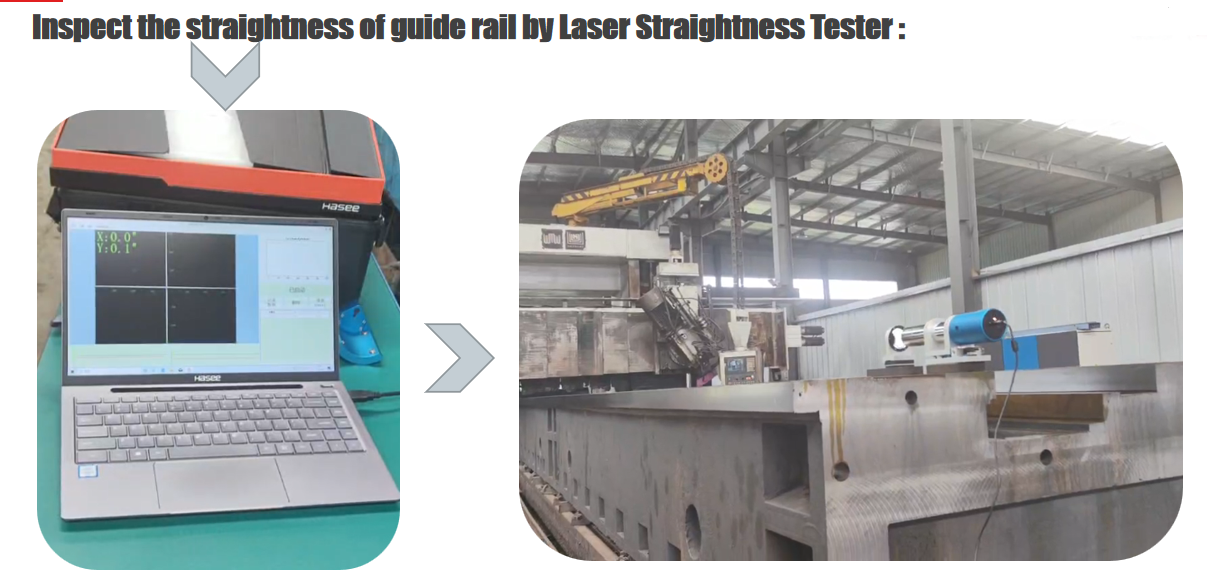

Strong machining facilities. Good quality and good accuracy machines are maufactured by good machining machines and skilled workers. We have two sets Germany brand Heckert guide grinder. The guide rail of the deep hole machines are the most important part,it decides the accuracy of machines. after ground by our grinder,the surface of the machine bed likes mirror. Our Japanese brand SNK five face milling machine will work on all the box parts of the BTA drilling machine. Chinee famous brand horizontal boring machine,planning machine,VMC machines,CNC lathe machines.

Most famous technicians. Our company has the most professional technicians. Six engineers totally. All of them had worked in this field for more than 15years. They are full of experience,can design the deep hole machines according to customers request.

Skilled worker teams. Nowadays,it is not easy to hire workers. Especially skilled workers. But our company has special management system to keep these skilled workers. So all of our machines are assembled by skilled workers.

Quality control system,from machine design,parts purchase,parts machining ,machine assemble,machine test running,machine packing,all the process,we have inspection system to warranty the deep hole machine quality.

We use ERP to manage the whole company running system. Every purchase parts,produced parts,machined parts are inspected seriously, all the asseble process are inspected by our inspector.

Our inspection instruments: Renishao laser inferferometer,laser linear meter,roughness meter,time aging meter and so on. ALl of our instruments are inspected every year.

We are the only deep hole machine manufactuer that can sign quality assurance contract and after sale service contract ,so all customer will rest assured after buy our machines.

In time after sale service:

Certificates of our factory:

Guanlu factory passed the ISO9000,Healthy certificate,CE and all necessary certificates.

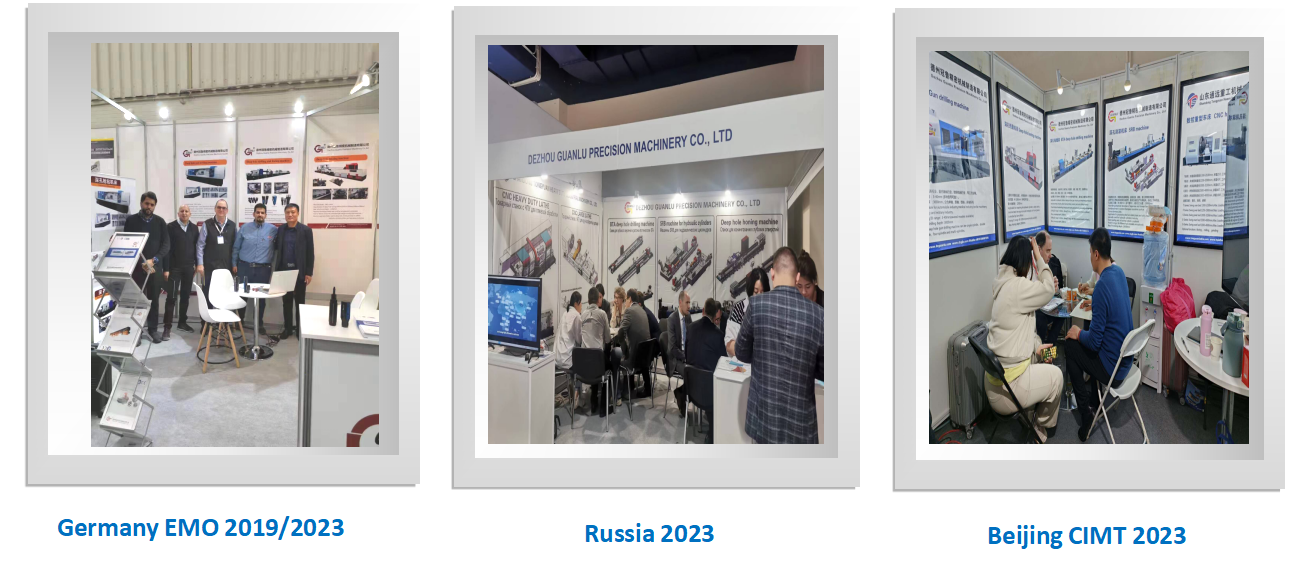

Some exhibition we have attended and some photos of our customer visiting:

Our deep hole machines have been exported to more than 50 countries,most of customers will come to visit us before place orders or inspect machines before shipment. See photos below:

Guanlu has been attended many international exhibitions:

Deephole machine package when shipping:

Machines will be packed by plastic film,all the small parts are packed into wooden box,while fragile parts such as panels are well packed and protected.Parts inside containers will be well fasten by irons and belts.

Contact me now:

Mobile/whatsapp/wechat: +8615165964868

Email: dzguanlu@dzguanlu.com

Contactor: Susan Lee