Dezhou Guanlu Precision Machinery Co.,Ltd

The machine is especially used for processing Drill collar

1.1 Machine processing capacity :

Drill hole diameter range: Φ30~Φ100mm

Boring hole diameter range: Φ40~Φ200mm

Processing depth range : 1000mm~10000mm

Workpiece length range : 1000mm~10000mm

Workpiece OD range : Φ89~Φ260mm

1.2 Machine functions:

Drilling and boring two functions .

Drilling hole : BTA drilling method , remove the cutting chips from the rear end through drilling bar .

Boring hole : Adopt push boring method , remove the cutting chips forward through the basic hole of workpiece .

1.3 Machine main structure:

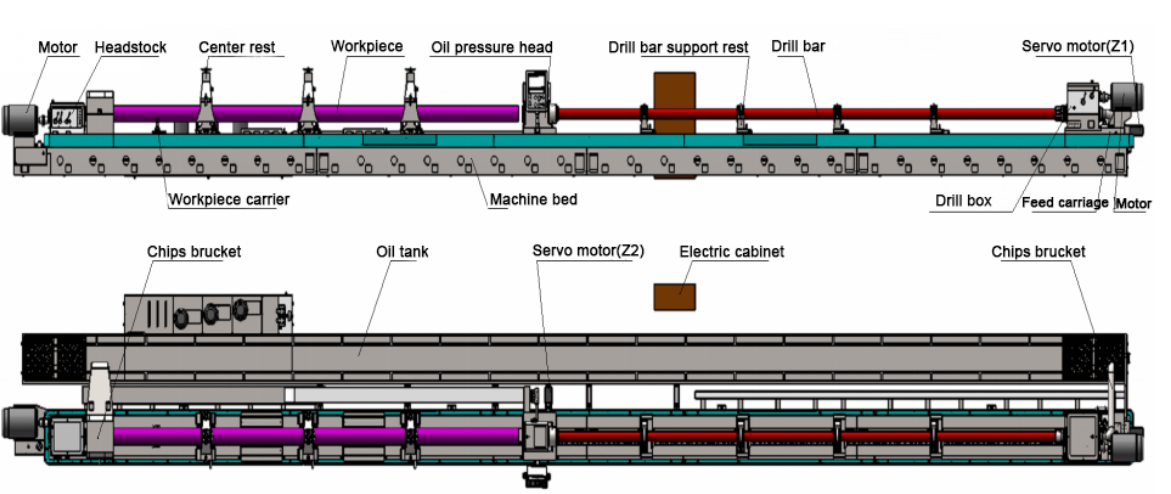

1.3.1 Main parts:

Machine bed, Headstock, 2sets workpiece carrier, Oil pressure head, 4sets drill bar support rest , Drill box , Sliding guide rail , Rack and Pinion, Coolant system, FANUC 0iTF plus CNC system, Electric cabinet, 3sets of four-point circular center rest , 1set of three-point center rest .

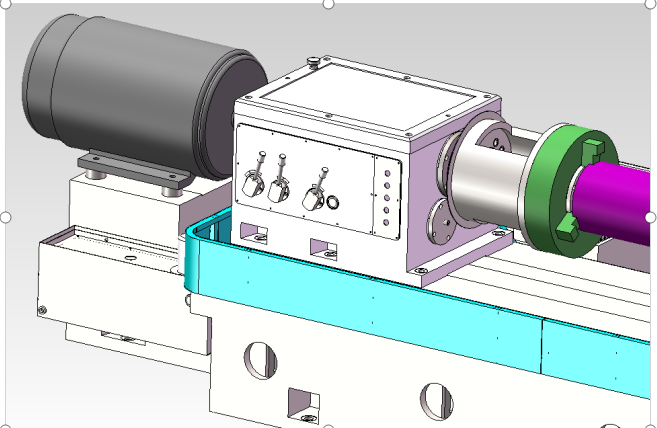

Headstock :

Used for driving the workpiece to rotate, 12-stage speed regulation by manual,adopt 30kw three phase asynchronous motor driving the spindle to rotate through belt and gear box . The manual three-jaw chuck is assembled in front end of headstock, used for clamping the workpiece.

The main motor connect with I axis directly through flexible coupling , to prevent from drive slippage problem when transfer large torque ; I axis as well as the pinion on it are made of materials with high tensile strength and high yield strength.

Headstock 3D sketch

Specification | Parameters | Remarks | ||

Working Capacity | Drilling hole diameter range | Φ30~Φ100mm | / | |

Boring hole diameter range | Φ40~Φ200mm | / | ||

Processing depth range | 1000mm~10000mm | / | ||

Workpiece length range | 1000mm~10000mm | / | ||

Workpiece OD range | Φ90~Φ260mm | / | ||

Machine Feature | Z1 axis (Drill box infeeding) | Movement speed range | 5~1000mm/min | / |

Servo motor torque/motor | 48Nm/7.5KW | / | ||

Z2 axis (Oil pressure head movement) | Rapid move speed | 3m/min | / | |

Servo motor torque/power | 27Nm/4.3KW | / | ||

Drill box | Rotary speed range | 81~480r/min | 6-stage speed regulation | |

Motor power | 30KW | Three phase asynchronous motor | ||

Headstock | Rotary speed range | 31~500r/min | 12-stage speed regulation | |

Motor power | 30KW | Three phase asynchronous motor | ||

Chuck | φ500mm | Manual four-jaw | ||

Others | Machine size (L x W) | 28mx3.2m | / | |

Machine weight (about ) | 35T | / | ||

Machine total power | 103KW | / | ||

Coolant System | Coolant pump motor | 7.5KW, 3grougps | / | |

Max. flow | 600L/min | / | ||

Processing accuracy :

Processing | Item | Accuracy | Remark |

Drilling hole | Hole deviation | 0.5mm/1000mm | Workpiece rotation,Drill depth and hole diameter ratio less than 100:1 |

Surface roughness | Ra3.2~6.3um | ||

Hole size | IT8~IT11 | ||

Fine boring | Surface roughness | Ra1.6~3.2um | |

Hole size | IT8~IT9 |