Dezhou Guanlu Precision Machinery Co.,Ltd

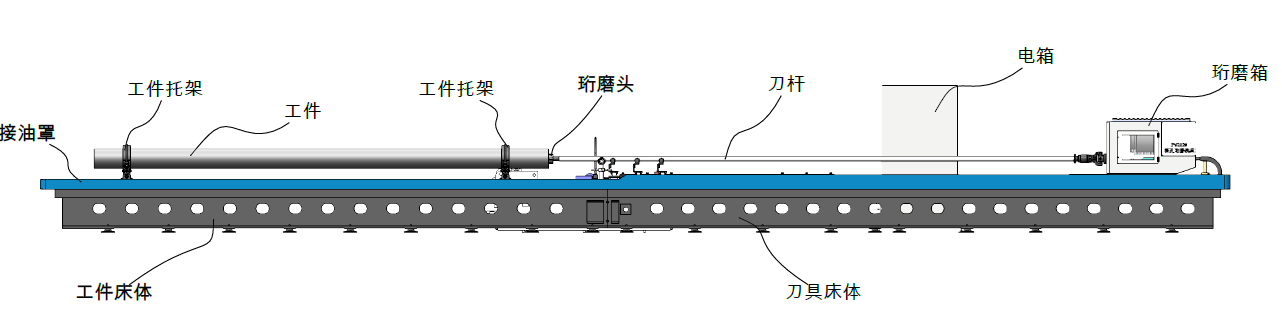

A high-precision honing machine suitable for large deep hole parts (such as oil cylinders), with intelligent feed, efficient cooling, and flexible clamping capabilities, which can ensure excellent surface quality and shape accuracy at the same time.

1. Basic specifications

Processing aperture : Φ 30-500mm

Maximum hole depth/workpiece length : 6 meters

Core application : Precision machining of deep hole parts such as hydraulic cylinders and air cylinders.

2. Core functional highlights

Two processing modes : Supports overall honing and local honing (can correct errors such as taper and ellipse).

Intelligent feed control : Servo motor controls the honing head, providing two key modes:

Constant pressure feed : Constant pressure, protects equipment, and can achieve extremely high surface quality (up to Ra0.2).

Quantitative feed: Forced feed can effectively correct the geometric shape error of the hole and reduce roughness.

Mixed Feed : Combining the advantages of both, Balancing accuracy and efficiency .

Efficient cooling and chip removal : Equipped with two methods: internal oil inlet and external oil inlet, ensuring sufficient lubrication, cooling, and cleaning of iron chips to improve surface quality.

Flexible clamping: The workpiece is placed on an adjustable V-shaped bracket and locked with a chain. Optional workpiece rotating spindle box to enhance process adaptability.

This is a high-precision honing machine suitable for large deep hole parts (such as oil cylinders), with intelligent feed, efficient cooling, and flexible clamping capabilities, which can ensure excellent surface quality and shape accuracy at the same time.