Dezhou Guanlu Precision Machinery Co.,Ltd

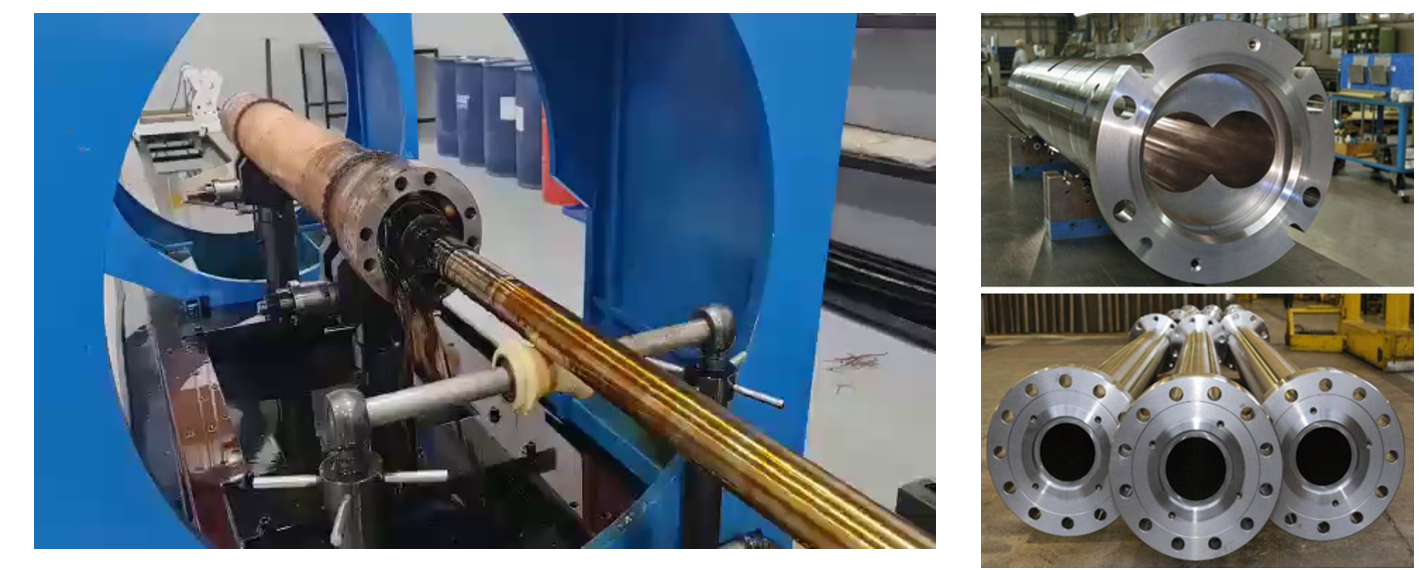

Guanlu deep hole honing machine is suitable for cylindrical jobs honing and polish process, and also works for precision parts,after worked by the machine,the hole accuracy can be up to IT6~IT7 ,surface roughness can be up to Ra0.2-0.4μm。It adopts partical honing,the parts can be modified by processing the taper, ellipticity and local aperture error, the honing machine is an ideal device for high precision and high efficiency ,we adopts PLC control of Delta,running steady,easy to adjust the speed. It is easy to warranty the hole size accuracy and reduce labor intensity.

Machine functions:

The machine is used for precision processing of various cylindrical workpieces with deep hole ,such as hydraulic cylinders and cylinders etc. .

It can do either whole honing or local honing ; When honing locally, the errors of taper, ellipse and local hole diameter can be corrected.

The expansion of honing head is controlled by servo motor, both constant pressure feeding and quantitative feeding could be realized .

Oil supply mode for honing head : External oil spray , Internal oil supply.

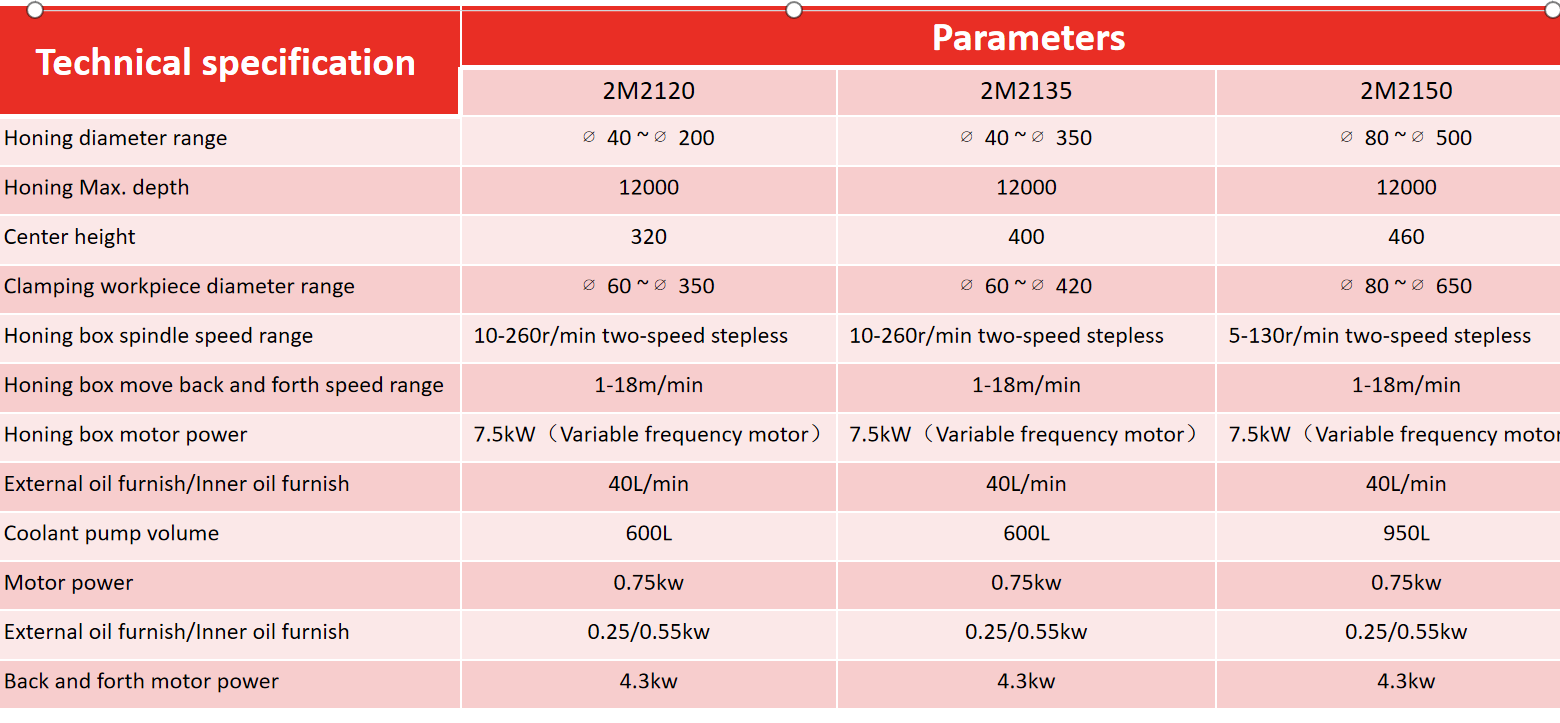

Deep hole honing machine popular models avalaible:(until honing to 2m diameter and 25m long)

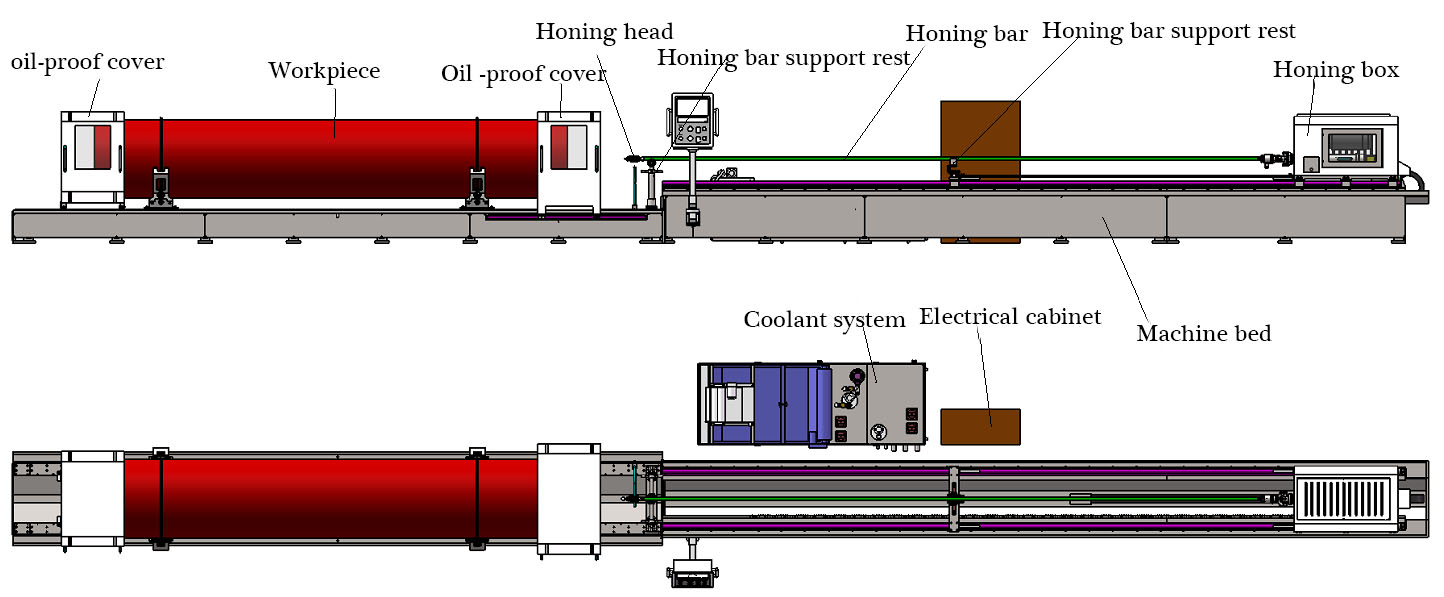

Machine main structure:

Machine main parts include:Machine bed, Honing box, 2set workpiece carriers, Honing bar support rest, Rack and pinion,Coolant system,SIEMENS PLC control system, Electric cabinet , and so on .

CNC axis :

Z 1 axis: The longitudinal feeding movement of the honing box (honing head reciprocating movement), the servo motor drives the rack and pinion mechanism through the reducing mechanism.

Z2 axis: Control the expansion of honing head, the servo motor drives the ejector pin to move axially through reducing mechanism .

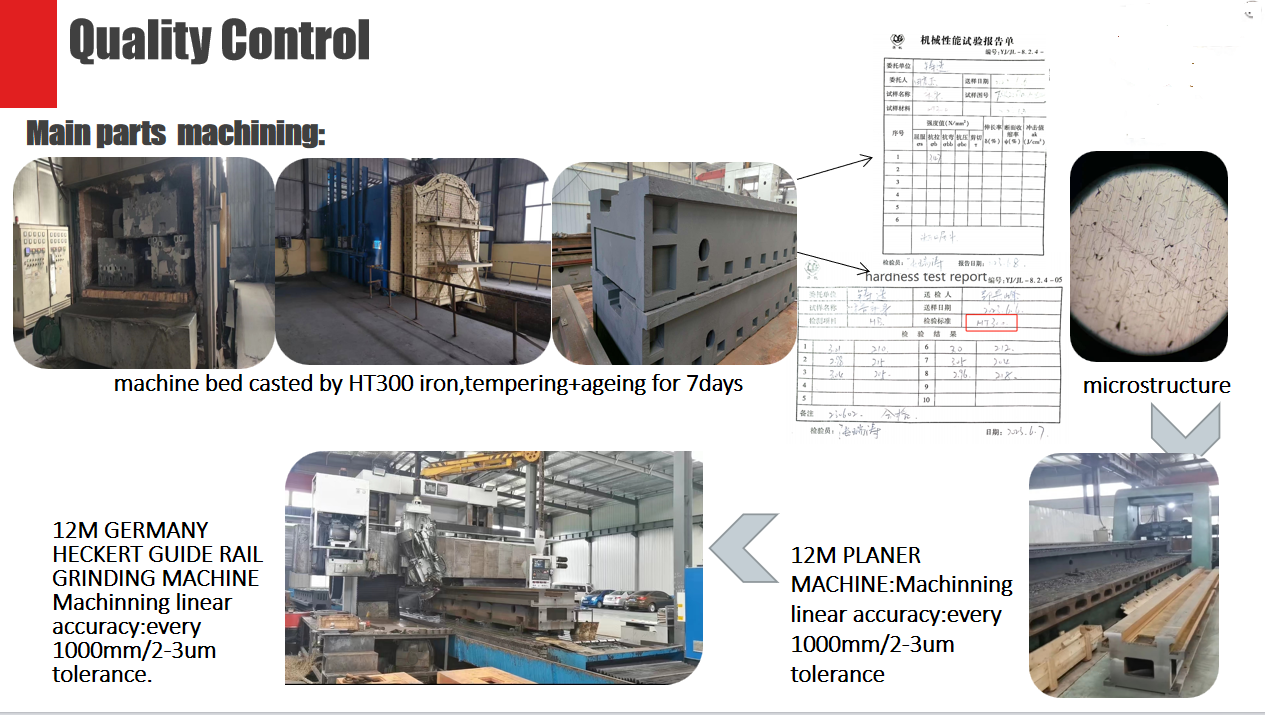

Machine bed :

Cast by super casting iron HT300, after twice aging treatments, the internal stress is eliminated, the structure and size are stabilized, and the mechanical properties are improved.

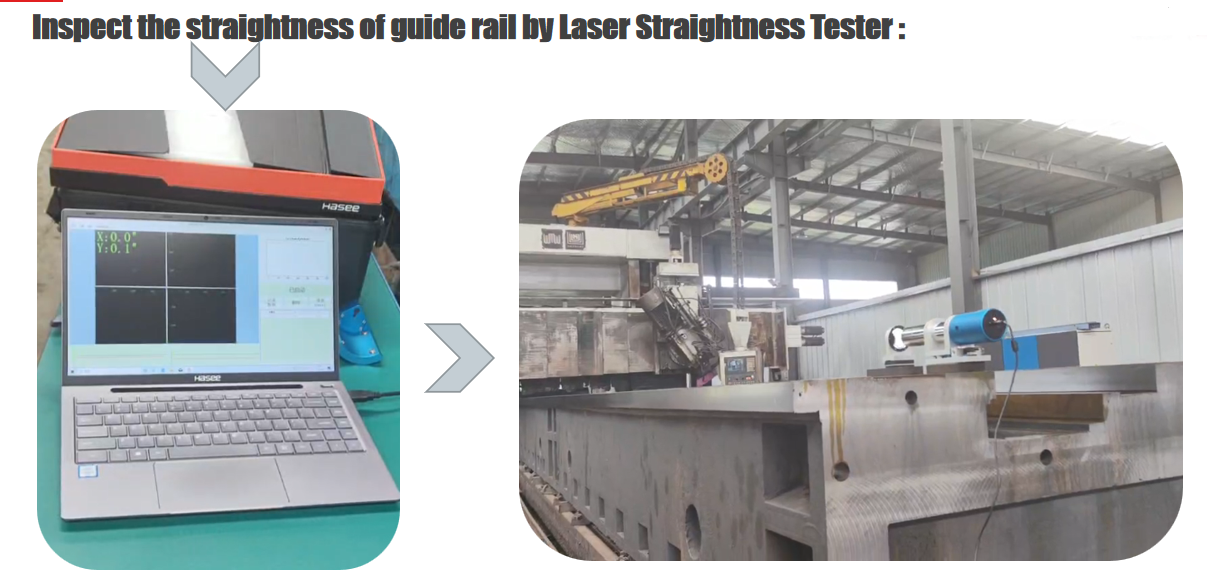

The linear guide rail (as shown below) is mounted on the machine bed , used for reciprocating movement of honing head,to meet the requirements of high speed during honing

The inner side of machine bed is mounted with rack, use for the feeding transmission of honing head. The transmission of rack is stable after precision processing and heat treatment .

Linear guide rail

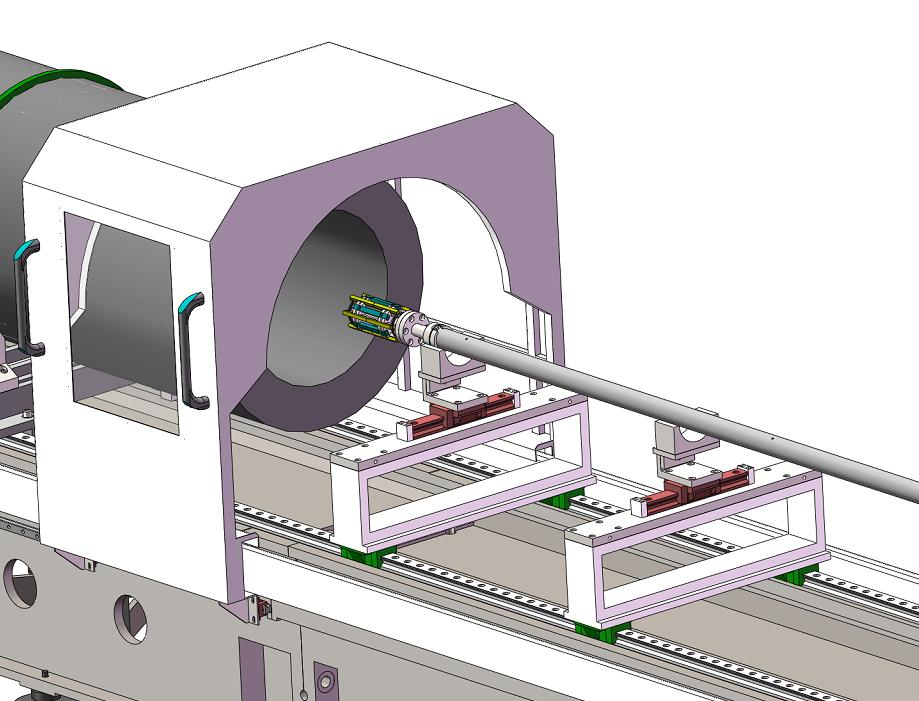

Honing box:

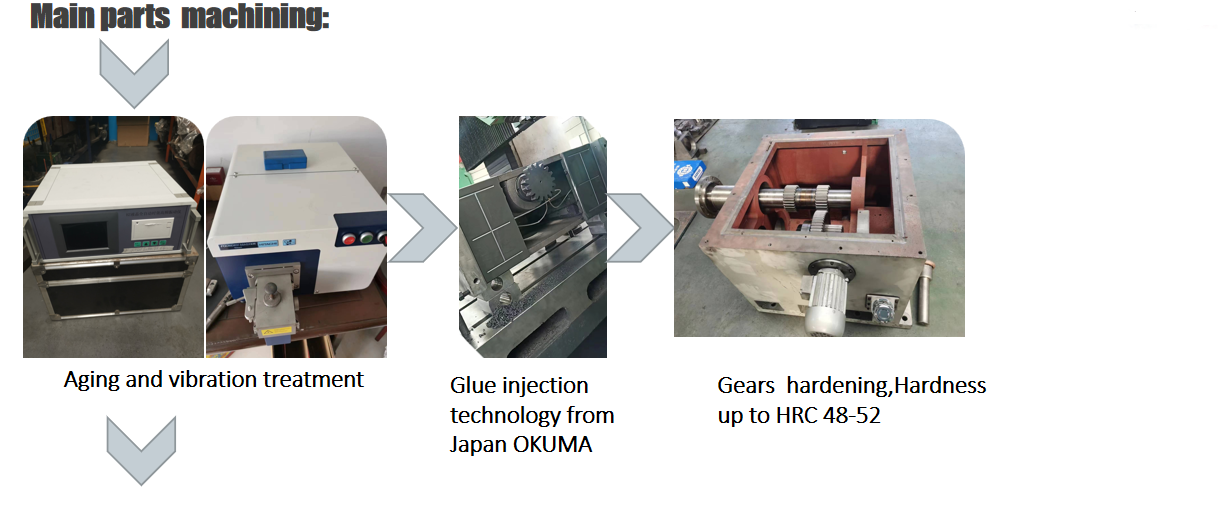

Used to drive the honing head to rotate, rotation speed stepless .

The variable frequency motor drives the spindle to rotate through the gear reducer, and the gear is ground precisely. The tooth surface of the gear is treated by high frequency quenching, and the hardness of the tooth surface is HRC48-52. In this way, the gear can obtain high strength, high hardness, high wear resistance and high fatigue limit, and can withstand large alternating load and impact load.

The spindle is supported by a combination of cylindrical roller bearings and thrust ball bearings. The spindle has high accuracy and can withstand large axial and radial forces.

In order to improve the service life of gears and bearings, lubricating oil is used.

Workpiece carrier:

Used to support the workpiece .

V-shaped structure, control the centering movement of two inclined edges of V-shaped through the positive and negative screw .

The workpiece is placed on the carrier, locked with pipe clamp chain manually.

The cushion plate with anti-slip function is assembled on the inclined edge of the V-shaped wokpiece carrier,  which can effectively prevent the workpiece from rotating in process of honing.

which can effectively prevent the workpiece from rotating in process of honing.

Honing bar support rest

Supporting honing bar in the process of honing and measuring.

2 sets, 1set is fixed on the machine bed, another set moves on the linear guide rail of machine bed .

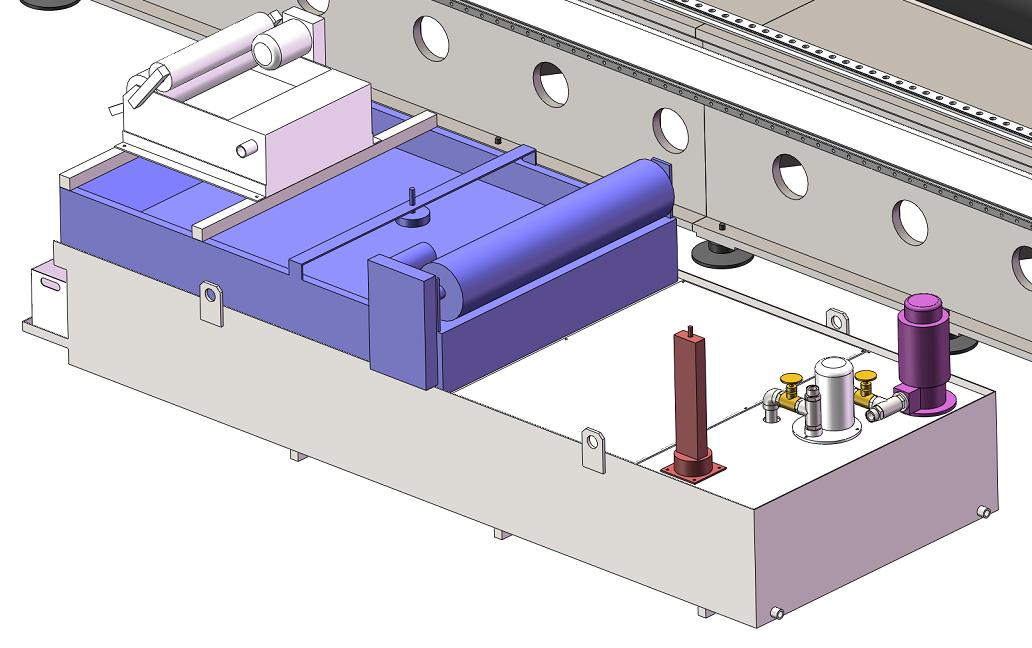

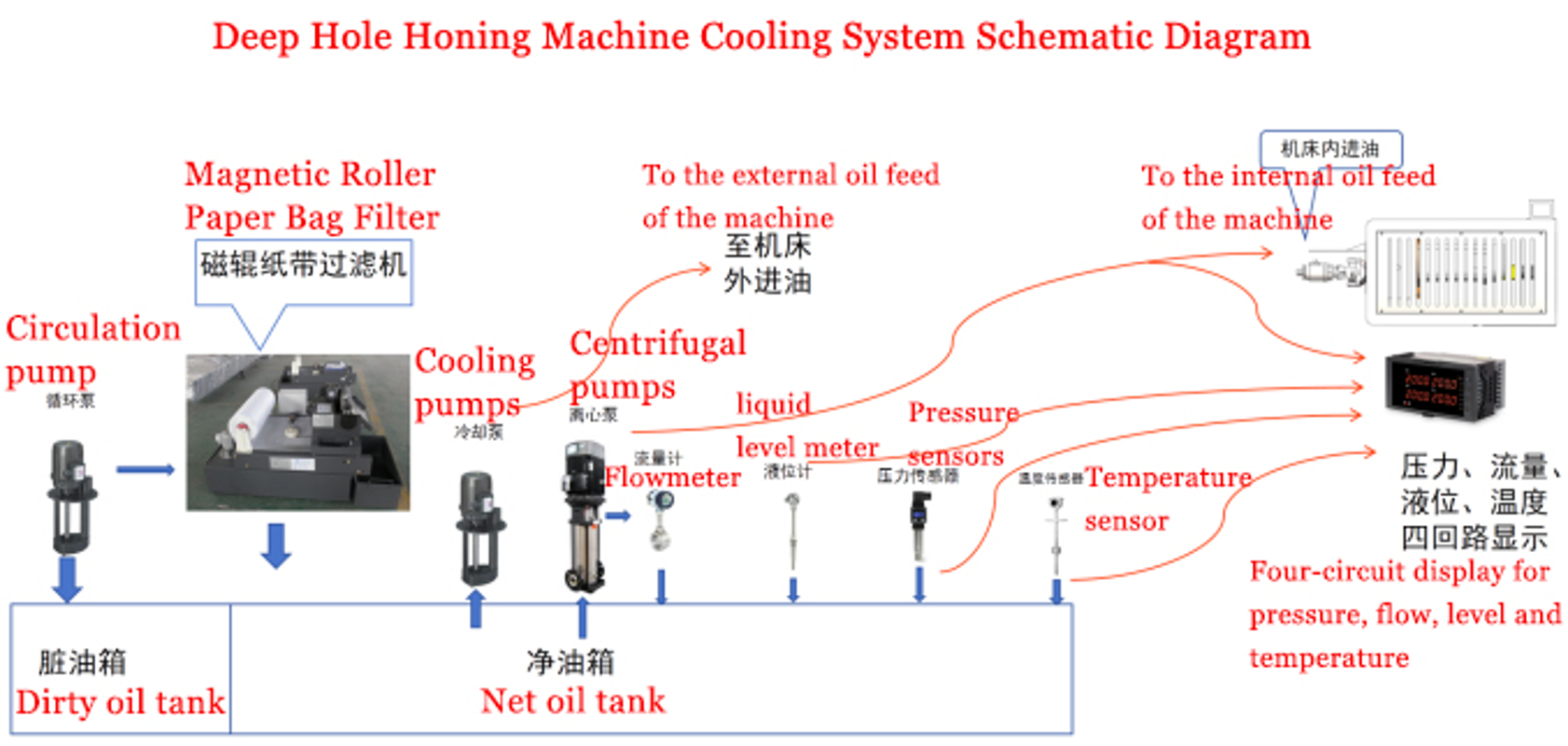

Coolant system

Supply the lubricating liquid for honing head .

Mainly composed of pumps, paper filter, magnetic filer,oil tank etc. .

Could provide external and internal two oil supply method for the honing head, it can be exchanged on the operation panel .

Lubricating system

The slider of guide rail for reciprocating movement of honing box is lubricated automatically through automatic lubrication station, and liquid level alarm is provided on lubrication station.

The honing box is filled with lubricating oil ,the gears and bearings inside are lubricated by the rotation of the gears.

Control system :

SIEMNES PLC control. An HMI touchscreen is adopted, allowing the reciprocating speed, rotation speed, and tool feed rate to be set directly on the screen. The operator station is mounted on the machine bed, and the operation panel can be manually rotated for convenient machine operation.

Electrical box:

Schneider low voltage electrical components:

Application industry: hydraulic industry,construction vehicle industry,aviation industry,machinery industry,coal mine machinery,moulds and dies industry,energy industry,water dam,car& engine industry.

Military Industry

Deep Hole Honing machine(Small hole honing) + Gun drilling machine + Broaching machine for military industry applications

Wiping machine configuration structure = with headstock (workpiece rotation) + closed center frame + chucks. Max. processing depth is 10000mm

Screw barrel industry:

For manufacturing precision engineering plastic extruders, the application of a deep-hole drilling & boring machine (for twin-barrel hole machining) coupled with a deep-hole honing machine is important.

Hydraulic Cylinder Industry:

The first choice for the hydraulic cylinder and air cylinder industry Used for precision machining various cylindrical deep hole parts such as hydraulic cylinders and air cylinders.

Optical fiber industry:

Quartz glass honing

Details about Guanlu and Guanlu Brand deep hole honing machine.

Dezhou Guanlu Precision Machinery Co.,Ltd,is founded in year 2011,we are the most famous factory in my local to manufacture deep hole honing machines. My city Dezhou is the production base of deep hole machines in China. Almost 99% BTA deep hole honing machines are produced here.

We have our own strongly machining facilite, Germany brand Heckert guide grinder,Japanese SNK five face milling center ,chinese most famous planner,VMC,Lathes,box boring machine,milling machine and so on. With these good machning facility,we could be able to manufacture the best quality and best accuracy deep hole machines,under proper management system,we could orgnize production properly,our delivery of machines are stable and in time,we also have some regular models stocks.

DZ Guanlu FACTORY advantages compared with other competitors:Our city is the production base of deep hole honing machines. Among these local competitors,our company is the first choice once clients has visited us and saw our deep hole machines. we have the absulately advantages than others.

Big workshops and Big factory: we have four workshops,one commercial office building and totally 70000square meters working area.

One workshop is 10000square meters.

Two other are13000 square meters each.

One is 8000 square meters.

All workshops are heavy duty,crane is 32tons,height is 14meters.

Floor foundation loading is 400tons.

SO we have capacity to manufacture heavy duty and long length deep hole machines.

Strong machining facilities. Good quality and good accuracy machines are maufactured by good machining machines and skilled workers. We have two sets Germany brand Heckert guide grinder. The guide rail of the deep hole machines are the most important part,it decides the accuracy of machines. after ground by our grinder,the surface of the machine bed likes mirror. Our Japanese brand SNK five face milling machine will work on all the box parts of the BTA drilling machine. Chinee famous brand horizontal boring machine,planning machine,VMC machines,CNC lathe machines.

Most famous technicians. Our company has the most professional technicians. Six engineers totally. All of them had worked in this field for more than 15years. They are full of experience,can design the deep hole machines according to customers request.

Skilled worker teams. Nowadays,it is not easy to hire workers. Especially skilled workers. But our company has special management system to keep these skilled workers. So all of our machines are assembled by skilled workers.

Quality control system,from machine design,parts purchase,parts machining ,machine assemble,machine test running,machine packing,all the process,we have inspection system to warranty the deep hole machine quality.

We use ERP to manage the whole company running system. Every purchase parts,produced parts,machined parts are inspected seriously, all the asseble process are inspected by our inspector.

Our inspection instruments: Renishao laser inferferometer,laser linear meter,roughness meter,time aging meter and so on. ALl of our instruments are inspected every year.

We are the only deep hole machine manufactuer that can sign quality assurance contract and after sale service contract ,so all customer will rest assured after buy our machines.

In time after sale service:

Deephole machine package when shipping:

Machines will be packed by plastic film,all the small parts are packed into wooden box,while fragile parts such as panels are well packed and protected.Parts inside containers will be well fasten by irons and belts.

More machines Guanlu could supply: BTA deep hole drilling machine,deep hole skiving roller burnishing machine,deep hole gun drilling machine,deep hole honing machine,vertical honing machine,CNC heavy duty lathe,CNC large lathe,pipe threading lathe and slant bed lathe.

Contact me now:

Mobile/whatsapp/wechat: +8615165964868

Email: dzguanlu@dzguanlu.com